page index:

Arbor runout

bevel cuts

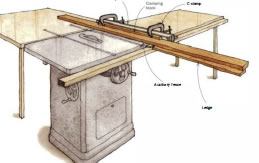

cleat running along table edge for wide [plywood/panel] cuts

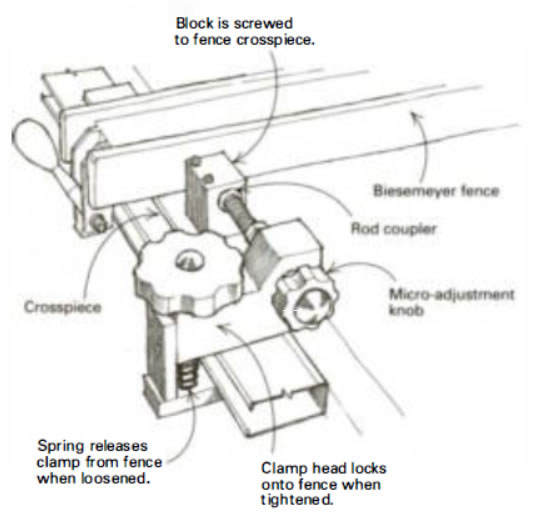

fence micro-adjust

fence - Universal Rip Fence & others

jigs & push blocks

jigs - featherboards

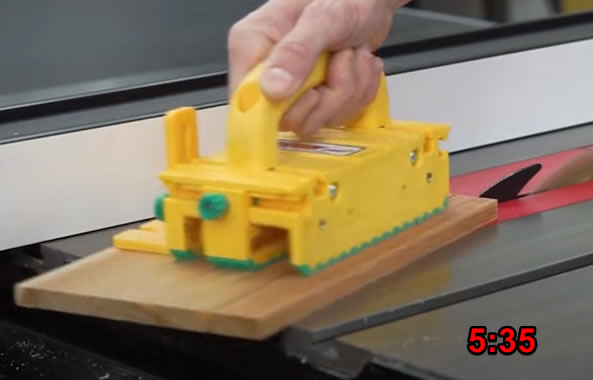

jigs - Micro-Jig GRR-Ripper

jigs -

tapering jig

jigs -

tenon jig

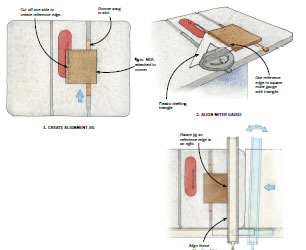

miter gauge squaring and angle setting

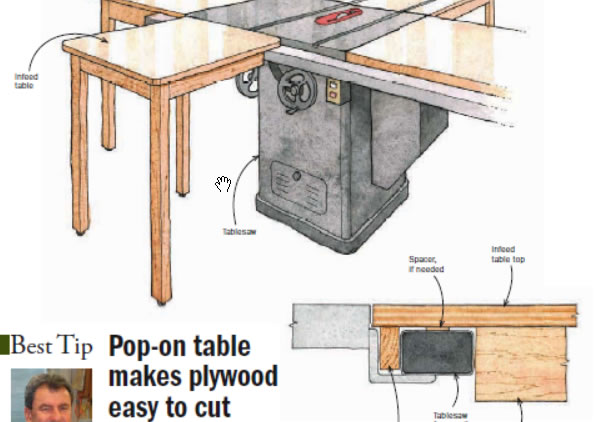

plywood cutting tips

picture frame miters

stop block

testing sled for square

Top Parallel to Floor

Top cleanup of rust

links:

Inspire woodcraft youtube video on marking blade so can find exact blade height

Inspire woodcraft youtube video on cutting blade width shim and using it for perfect dados and grooves

Inspire woodcraft youtube video on differet technique cutting blade width shim and using it for perfect dados and grooves

Inspire woodcraft youtube video on making perfect half-laps using shims created with techniques above

video on fixing it with stone in router

checking it as well as blade flatness video

runout is checked with the same tooth rotated around

to check blade flatness leave the dial indicator in one spot

fww 0225 Page 37 attach an L-shaped fence to a miter gauge to prevent tear out

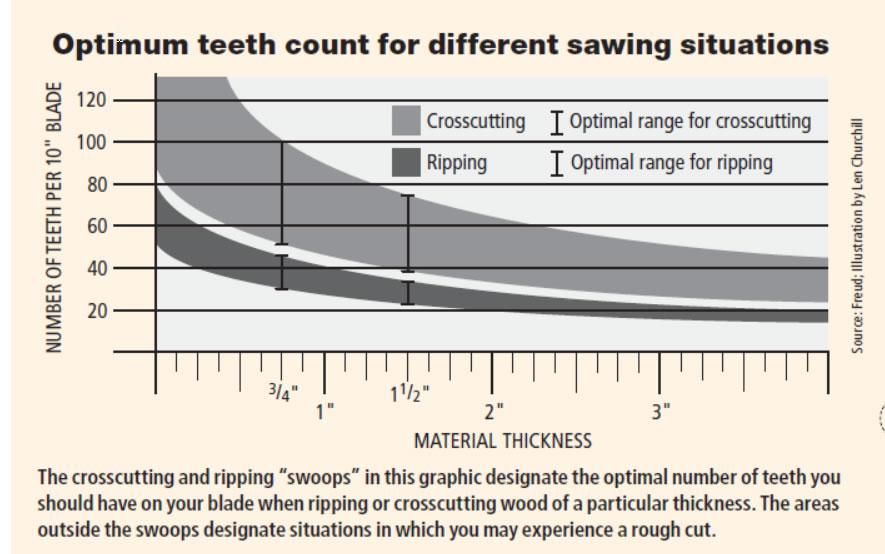

fww 0267 combination blade tool test pdfp44 - The Premier Fusion P410 I bought got both best overall and best value

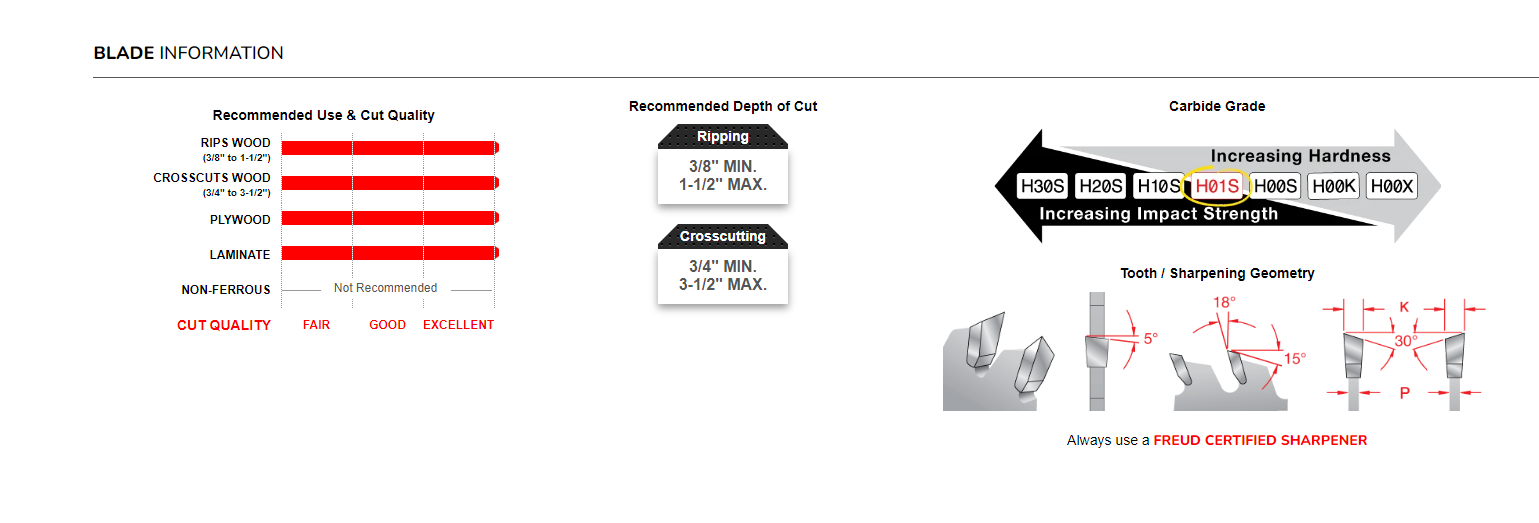

Shopnotes 112 pdfp52 p48 describes the blade geometry

= Next Generation with New Fusion Trio Tooth Geometry" on packaging

= 30º Hi-ATB for slicing through plywood and melamine, a double side grind design for delivering polished cross cuts, and an Axial Shear Face Grind that zips through wood and sheet goods with minimal resistance

Ideal For: Crosscuts (3/8" to 3-1/2") & Rips (3/4" to 1-1/2") wood, laminate, veneered plywood, hardwoods & melamine.

this is the one that needs the face of the teeth lightly ground every 4th sharpening onf the top

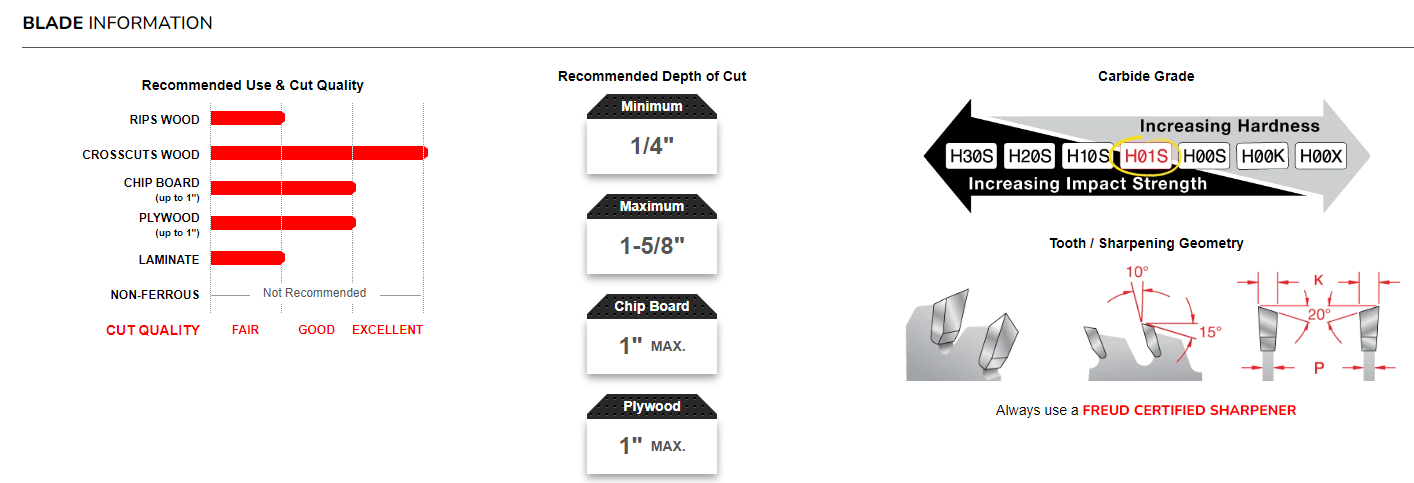

Ideal For: Ultimate crosscutting blades for glass-smooth finishes when crosscutting hard and soft woods, so no sanding is required. Depth of cut (1/4" min to 1-5/8" max)

Ideal For: Smooth, Fast Heavy-Duty Ripping. Depth of cut (3/4" to 2-3/4").

see ...\table saw grizzly 5hp 2021-12-20\2024-09-02 Freud rip blade

Family Handyman 2022-04 see p36 & p38 p34 35 36 37 38

PWW 2004-11 pdfp31

Family Handyman 2022-04 see p38 p34 35 36 37 38

Dado Blade Review on Rockler

2023-06-22 with Forest blade stiffener on Grizzly table saw using incra5000 I couldn't cut two inch thick stock without the blade stiffener beating up the bottom of the zero clearance insert / eventually wearing through it

woodsmith 0194 pdp43 3rd to last paragraph - if panel is more than twice as wide as long, don't use rip fence

woodsmith 170 p12 tips for cutting plywood on tablesaw

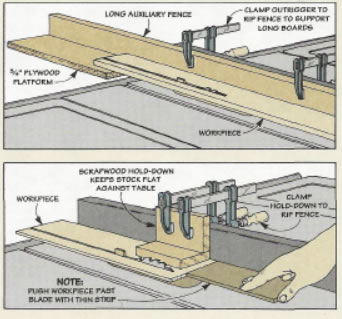

shopnotes 009 p23ish outrigger attached to fence and hold down attached to fence

similar outrigger in fww 0178 pdp14

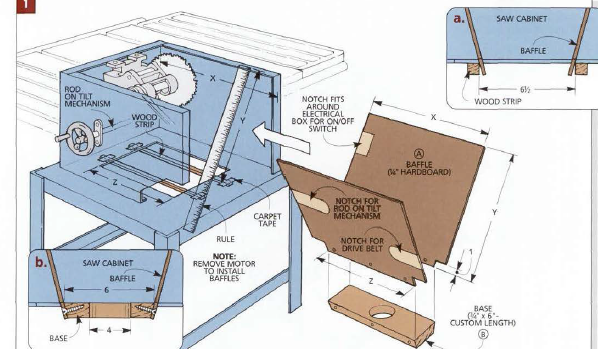

Workshop Essentials.pdf Contractor saw dust collection without taking stand apart pdfp103

instructables post on making a dust collection plenum for craftsman saw

another good post on same topic

Shopnotes 28 p28 creating jobsite saw dust collection enclosure

FWW 127 pdpf 32

FWW 231 Supercharge your rip fence by Bob Van Dyke

fence base with toggle bolts on the back to attch to fence so clamps at the top don't pull it out of square

then bolt on face sacrificial fence for rabbets or a tall fence

FWW 0237 pdfp 60 The Incredible L Fence by Bob Van Dyke

Jim Tolpin's design PWW 2004-02 pdfp65 p84

PWW June 2007 pdfp18 saddle fence to attach featherboard, spline jig, or simple tennon jig

Wood 095 p53 Feb 1997 Unifence gets best all around.

i think this post was where i first learned of the Peachtree Uni-T-Fence

differnt similar fence i was looking at for craftsman saw when it wasn't available

this is a thread from someone who made their own and another

simple unifence jigs

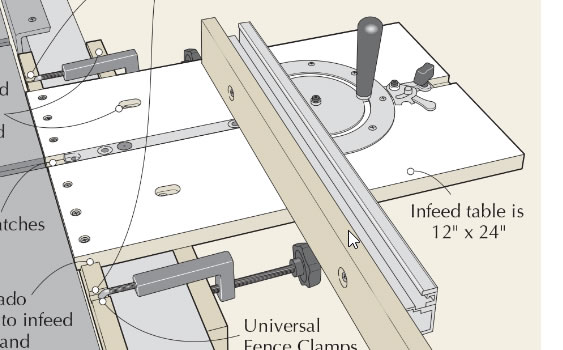

tablesaw infeed table I am building (local .pdf)

short video to make this cut. not sure it would ever be necessary - why not just flip board and cut on tablesaw with bevel?

Am Woodworker 2007-01 pdfp 53 4 useful simple jigs: small parts, thin rip, crosscut sled, taper cutting

woodsmith 229 crosscutting long panels

two roller stands with panel clamped to 2x4 across them

Table Saw Infeed Table / Miter gague extension to allow miter gauge to cut larger material (local .pdf)

FWW 0242 pdf14 simple sled for jointing and tapering at on tablesaw

Woodsmith outfeed support attached to saw horse (local .pdf)

small parts ripping sled from Woodsmith

FWW 0243 simple jig to square miter gauge and align fence

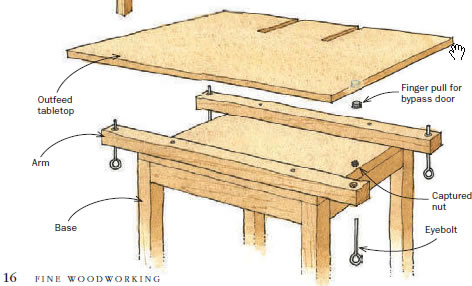

infeed table FWW 0220 pdfp12

use the idea of the top being leveled rather than the bottom FWW223 p16

Infeed table FWW 0220 p12

45 and 90 setup blocks stored with magnet under fence rails Shopnotes 120 pdpf7

cutting small parts safely with offcuts corral

magnetic version I should make using on/off magnets - search for "table-magfeather.pdf"

stacked featherboard - woodsmith 184 page 6

see also jigs#gripper

search for "ripper" to find Micro-Jig GRR-Ripper pushblock files

\woodworking\000 techniques and specific tools\tablesaw\GRR-Ripper 3D pushblock #gripper push block

quick start video 8 mins

full instructions video 37 minutes

playlists

from ch 2 foundations

3" wide without side part installed

5" wide capacity with balance support on 1/2" leg riding against fence

0:44 chapter 3 1/8" accessory can replace a leg (use top mounting screw holes) or attach to the side of a leg (use lower mounting screw holes)

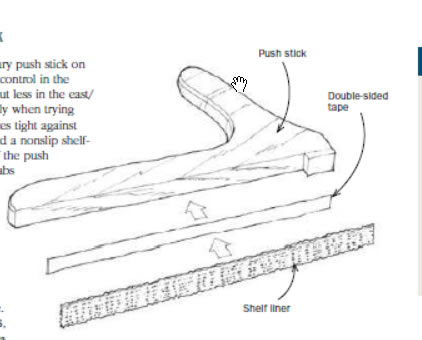

push stick design FWW 0189 pdfp18

simple jig using dial indicator to align blade to slot and fence to slot FWW 0221 pdfp14

PWW 2004-11 pdf71

fww 0304 pdfp20 make stopped cuts for easier cutting of last 2 sides

tapering jig runs over fence and uses fixed portion near blade for taper on a wide panel FWW 0193 pdfp14

FWW 0191 pdfp30 p30

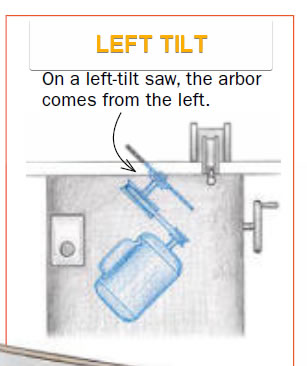

left tilt benefit

safer when making beveled ripcuts with the fence to the right of the blade

workpiece is not trapped under the spinning blade and the offcut is free to slide off to the left

left tilt disadvantage

changing blade thicknesses leads to a loss of fence-tape accuracy; right side of the splitter won't be at its ideal safety setting

best solution is to buy blades of the same thickness

right tilt benefit

tape on the rip fence always reads the distance accurately between the fence and the right side of blade, splitter always in safest spot

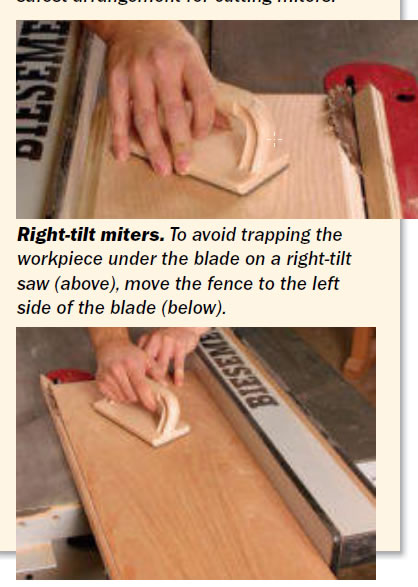

right tilt disadvantage

beveled ripcuts can be more dangerous with the fence to the right of the blade. offcut can ride up the blade's rear teeth, or the workpiece can get trapped under an angled blade. Also, the opposite bevel gets wedged under the rip fence

American Woodwoker January, 2006.pdf pdfp8

15 table saw Hacks especially 4, 5, & 6

Building Cases With Rabbet Joinery ShopNotes "Table Saw Secrets - Tips, Techniques, Plans & Projects.pdf" pdp30 p32

clean gears with naptha, then lubricate with Dry Moly Lube (CRC makes one) FWW 0237 p84

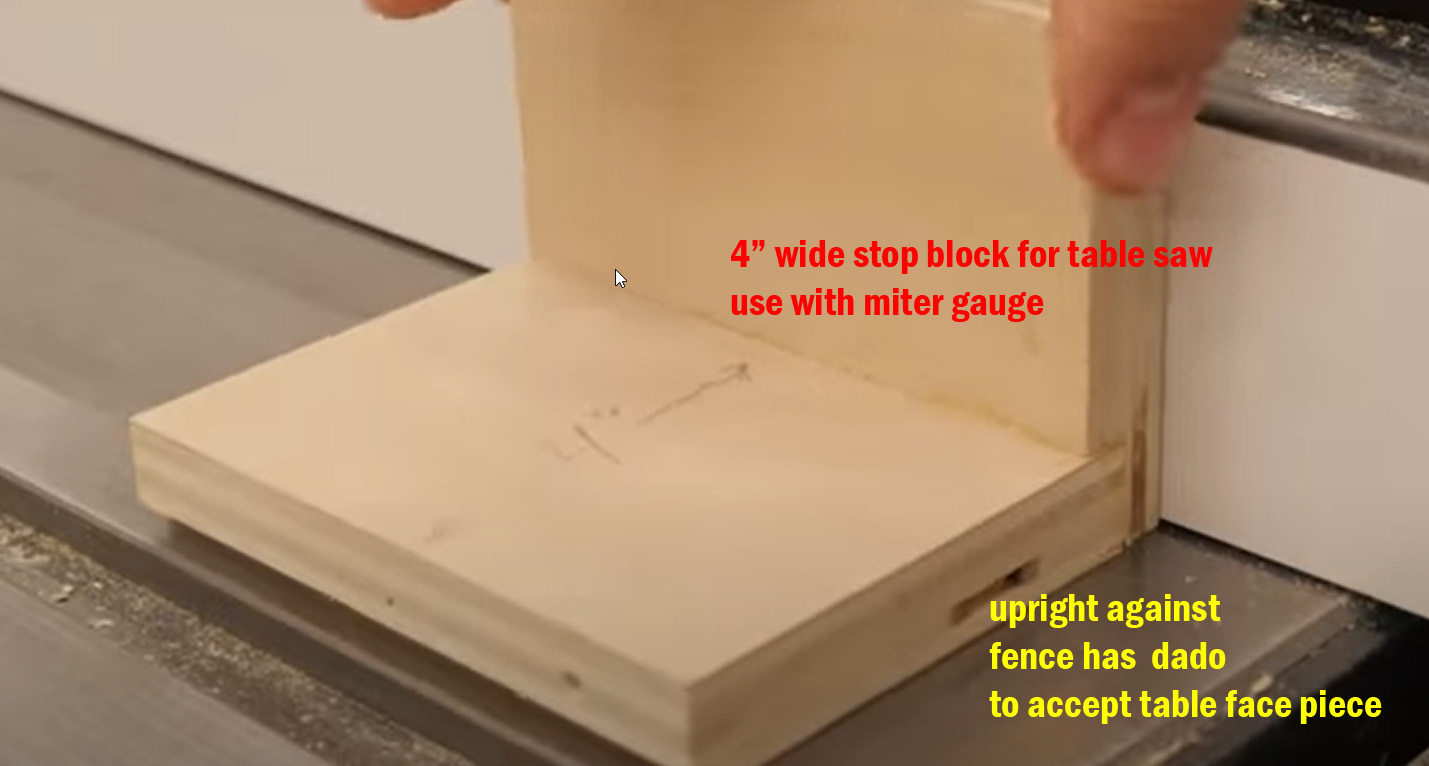

2025-05 video on someone tapping holes in grizzly miter gauge "adding a waste board..."

mounting a pipe below fence rail to hold stop for miter gauge on long pieces

build a quick 30-60-90 triangle to allow angles beyond miter gauge range AmWW Jan 2011 pdfp13

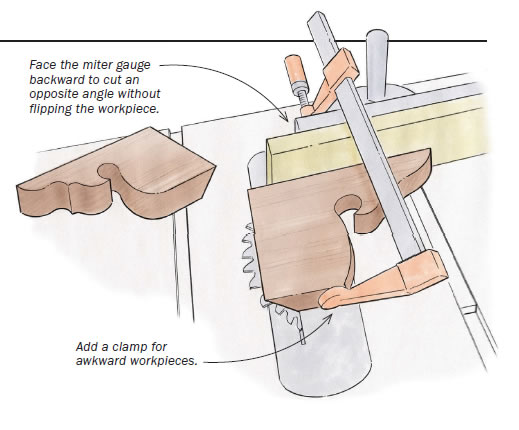

fww 0305 p16 reverse the miter gauge to reverse the angle

to allow some cuts not possible the other way (since blade only tilts one way)

2024-01-21 PWW Accurize Your [Contractor Style] Table Saw (local .pdf) adjusting trunions, using dial indicator to check blade angle & miter gauge parallel, etc.

easy to adjust trunion brackets for contractor saws

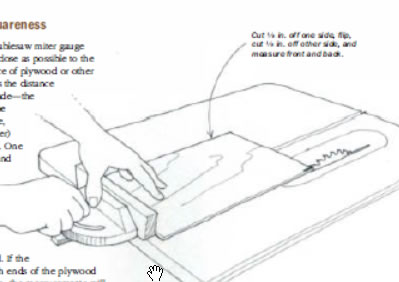

FWW 0184 p 16 true edge against miter gauge; cut one side; flip over (true edge still agains miter gauge) and cut again; error is 1/2 x ABS(top width - bottom width)

Woodsmith 151 p6 miter gauge squaring with folding wedges

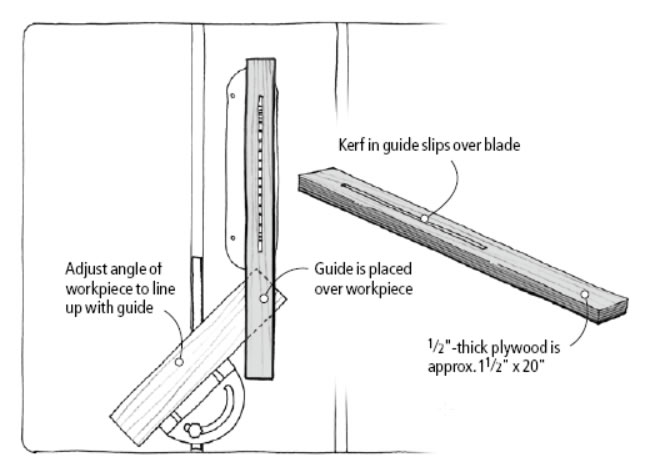

very simple jig for setting miter gauge angle to an angle drawn on the workpiece PWW June 2005 p18 pdfp10

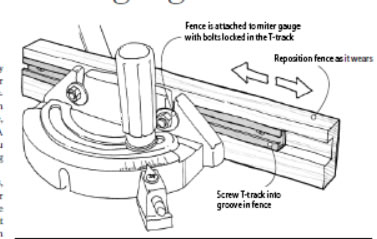

sliding miter gauge fence PWW Nov 2006 pdfp10 p20

checking miter gague for squareness [Fine Woodworking 0184] pdfp16 p16

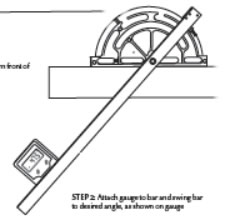

setting miter gauge to particular angle with digital level [Popular Woodworking Apr 2009] pdfp11 p18

miter gauge clamps for small parts and dowelsShop notes 90 pdpf46

see "Taunton's Complete Illustrated Guide to Tablesaws.pdf" pdfp150-151 for tips on where to stand, etc when ripping full size sheets of plywood

similar in pww Nov 2004 #144 pdfp38

in general, the falloff piece on the left side of the blade remains where it is at termination of cut and piece between blade and fence is pushed all the way past the blade

!!! DON'T REACH OVER THE BLADE !!!

see "Cleat running along table edge for wide [plywood/panel] cuts" = #cleat on this page

woodsmith 170 p12 tips for cutting plywood on tablesaw

woodsmith 0194 pdp43 tips for cutting plywood on tablesaw

both recommend standing at far left corner to start, then as moving cut forward move closer to the fence (and thus the center of the plywood width)

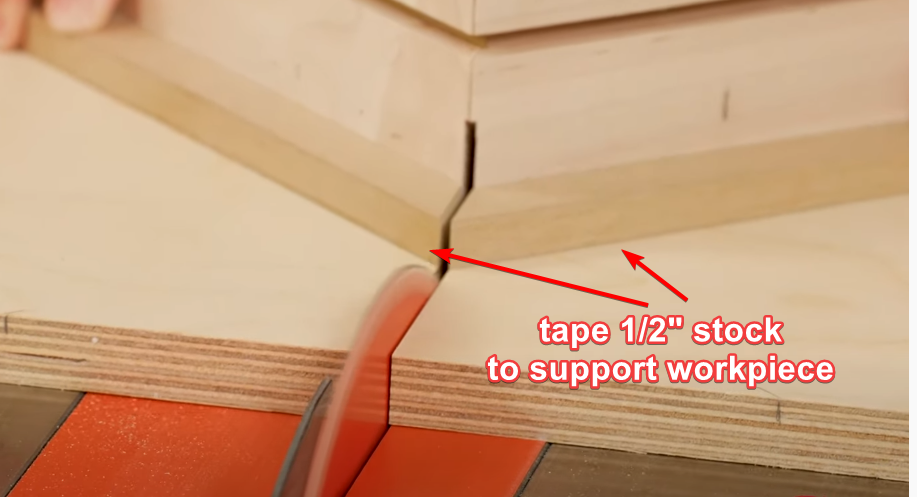

Wood Magazine youtube video on sled and adding 1/2 stock to hold up picture frame piece

see section Testing Sled for Squareness

tip for using dovetail clamps to make small adjustments when building a sled (local .pdf)

kings fine woodworking version with super detailed instructions (local .pdf)

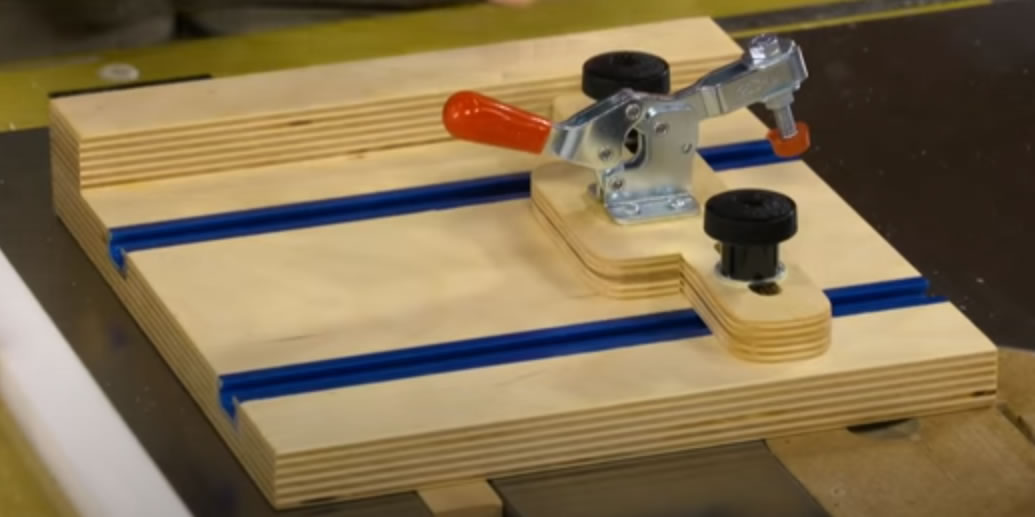

Woodsmith: Small Sled Hold-Down (local .pdf)

FWW 0089 pdf72 "A Tablesaw Ccrosscut Box" [2025-03-08 found screen capture from 2021-01-01]

crosscut sled for small parts Shopnotes 120 pdfp5

refreshable zero clearance insert allowing multiple bevel anglles FWW0299 pdfp12

soup up your crosscut sled FWW 0219 pdfp24

foolproof crosscut sleds fww 0227 pdfp42

base in 2 pieces, put runners on base pieces at the bench, then make zero clearance cut "I lightly clamp the runners sung agains the insdie edge of the slots when gluing on the front fence (see pic p45)"

quick sled with a couple nice features tslots and sliding fence - just one runner part isn't so great. PW Apr 2007 pdfp 11.

I took a screen capture of it 2022-08-03 and now on 2023-01-01 it doesn't look so great.

"Workshop Essentials.pdf" pdfp81 version with a nice hold down feature

The one I am building is from ShopNotes 130 pdfp20 - consider making mirror image so mostly over tablesaw extension

see tips ~pdfp26

ShopNotes 130 pdfp26 aligning self stick measuring tape

Fine-Tune Miter Sled on Woodsmith site (local .pdf)

2023-01-12 small parts taper jig. there had been showing up in my google woodworking feed for several days, but it is gone now.

this video is nearly the exact same thing.

from stubby nubs video

Magnetic stop block (local .pdf)

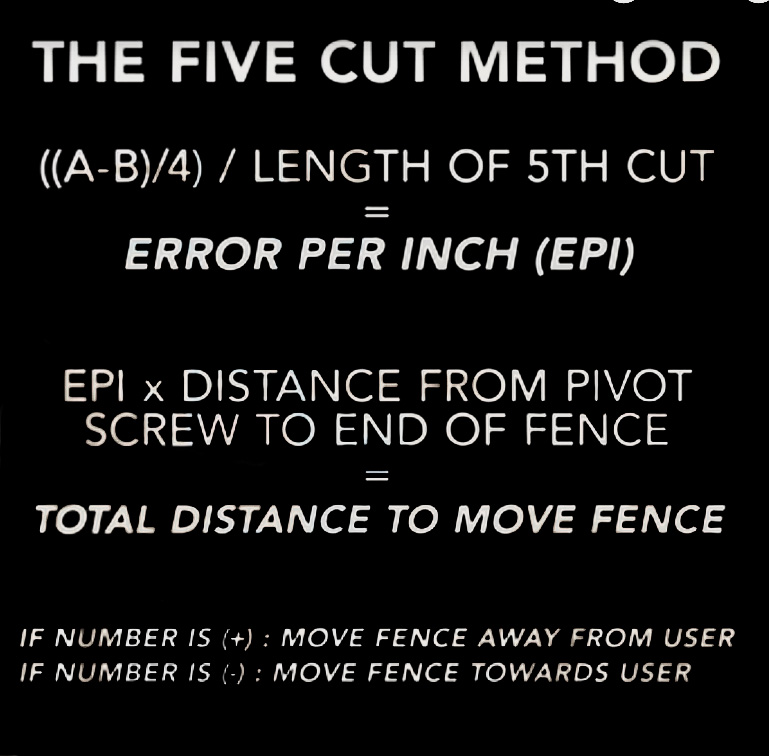

Jonathon Katz-Moses "Ultra Square Medium Sized Crosscut Sled" video giving credit to Ng seek to ~8:15

he cuts on right side of blade as I do on Grizzly saw, but since my pivot point is one the

left of the fence instead of the right I must reverse signs, thus

for me positive move closer to user, negative move away from user (see "Mitigating Human Errors in Crosscut Sleds and What's the Maximum Allowable Tolerance?" too)

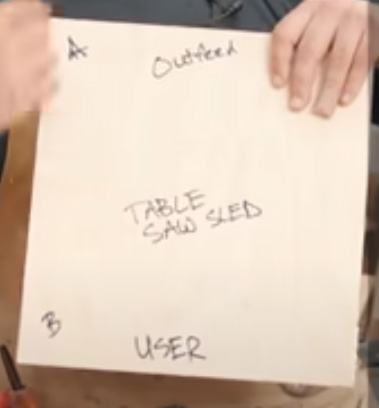

William Ng video on his testing for squareness '5 Cuts to a "Perfect" Cross-Cut Sled'

Formula for calculating Error: (A-B) ÷ 4 ÷ Length of 5th cut x Distance between pivot point and the point of adjustment = Error

this post explains Ng cuts on one side of blade and Katz-Moses on the other so calcs are different

easy Testing for Square cuts on tablesaw with calipers (local .pdf)

another method [Popular Woodworking Feb 2006 pdfp12 p24] is cutting board, then flipping piece so far edge is against fence and see if cut lines mate

Shop Notes 115 pdf p46

This post on woodworkingtalk.com indicates it isn't necessary but might be convenient in some cases

ShopNotes "Table Saw Secrets - Tips, Techniques, Plans & Projects.pdf"

Shop-Made Dial Indicator Holder for testing parallelism pdp11 p11

PWW tune up part 1 2 3

super detailed pww article on adjusting trunions if blade not parallel to miter gauge slot often resulting on burning

Craftsman saw arbor tuneup / replacement on archive.org

to check blade at 0 bevel pdfp14 take out throat and use long combination square Am. Woodworker 2003-01

Taunton's Complete Illustrated Guide to Tablesaws.pdf pdfp 114 & 115

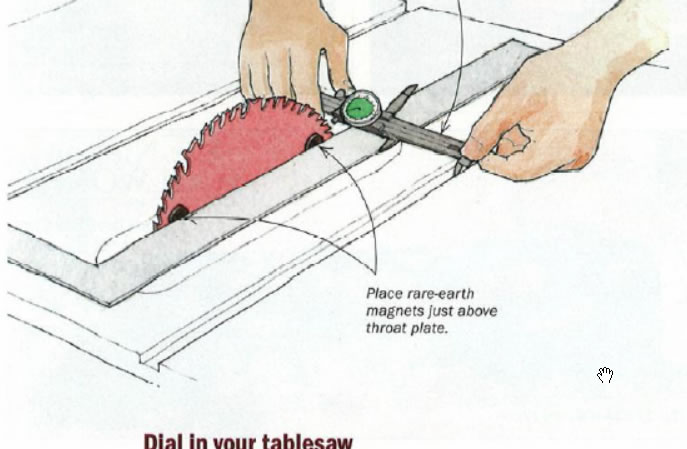

using dial indicator with simple jig to test miter slot to blade  , then fence to miter gauge

, then fence to miter gauge

i used miter gauge instead of building jig

"acc-TableSawBladeAlignment.pdf" shows simple home made version with brass screw instead of dial indicator (2024-07-26 finally removed samsung note from 2020-12-11)

dial in your tableasaw with magets and a square "FWW.Tune.up.tools.pdf" p10

Woodsmith 266 p 22

"acc-TableSawBladeAlignment.pdf" simple home made version with brass screw instead of dial indicator

fww223 p88 when checking blade 90 deg to table, don't rely on the stop. Adjust stop so slightly past 90 is possible and set to 90 with a square each time as sawdust gets between stop and trunion so it won't always be 90

I should be using this technique for Grizzly saw

tablesaw tips and tricks from wood mag\img102.jpg p10 making the most high quality ones using dish carving bit and jigsaw to create relief

Peachtree Woodworking zero clearance inserts

PWW insert using epoxy with countersinks on either side to lock it in place (dumbell shaped) (local .pdf)

Shop-Made Zero-Clearance Table Saw Insert | Woodsmith

FWW 0253 p16 use forstner bit to remove material if blade to high

Wood 237 p16 pdfp18 removable insert for Craftsman style saw (local .jpg)

Adding a riving knife slot from woodmagazine.com (local .pdf)

easy zero clearanace throat plate for craftsman tablesaw (local)

i think this is the one i used years and years ago

huge selection of phenolic and uhmw inserts

this guy used 3/8"x1/2" rabbet bit, though in part 1 he claimed he needed a 9/16" wide rabbet

this video is British guy that just glues masonite onto thicker piece below

last updated: Thu 2026-02-05 7:38 AM