FINISHING

child pages:

page index:

Arts & Crafts / Mission White Oak finish

brushes

cherry

dyes

Finishing both sides

Gel Varnish

inside of a drawer finishing

Lacquer

Maple

misc

oil finish Tried and True Varnish Oil

oil finish Glancy's No. 1

outdoor finishes

Paint

Polyurethane

Purchases

Shellac

Solvents

sprayer

Staining

Understanding Wood Finishing - Oil, Film Building, Stains, Solvents

Varnish

Water damage repair

wax

Wipe-on Finishes

Arts & Crafts / Mission White Oak finish

transtint analyne die color i have is "dark mission brown"

analyne dye never goes bad even if mixed

gel stain I have General Finishes Oil Based Gel Stain Candlelite color pint was $16.99 in ~2022 at Woodcraft (item 826966)

2025-09-02 PWW mission finish (local .jpg)

Arts & Crafts Finish Safe and Simple (no fuming) FWW 157 July 2002

p42

same article in

"2015 - Arts & Crafts Furniture.pdf" pdfp 108

I think I kind of used this when staining phone vise base 2023-10-05; the magazine calls for Reddish Brown dye stain and Walnut Pigment Stain.

2025-03-31 I went back and found this is the magazine article in the picture when I texted Andy 2023-09-28; the pic also had the transtint "dark mission brown" and Candlelite Gel Stain. I think I was going for the finished color in the pic but I was using the Stickley recipes below

2024-01-12 I found a bookmark and .pdf download from 2021-05 for these modern Stickley recipes from here that I may have used when buying the dye and stain at woodcraft

I probably bought the materials for recipe 5 but I need to check.

there was also a bookmark to this video and this article that has pretty detailed steps

Mission finish from Wood 158.pdf pdfp48 - uses roofing tar in recipe to recreate fuming look

FWW 0278 pdfp 79 Arts and Crafts Finish by Tom McLaughlin

- sand to 220

- dampen with rag to raise grain (since water based dye coming up)

- let it dry, then "sand lightly with fine sandpaper" = 220 or 320

- walnut colored dye to darken wood but leave muddy pigments on surface

- two coats of 1 1/2lb cut shellac. he likes amber (which has wax) but final coat is unwaxed

- at least 2 hours between coats, sand with 320 or 400 after second to raise white, powdery residue

- work multiple different colored glazes into the open grain

- 1st brown then seal with 1 1/2 lb cut blond or amber wax free shellac; lightly sand with 320 grit

- adds classic reddish-brown

- 2nd black then seal with 1 1/2 lb cut blond or amber wax free shellac; lightly sand with 320 grit

- work into grain in circular motion then along grain; let it sit for a while then wipe off

- emphasises grain and figure

- leaving glaze on the surface, especially near joinery, enhances patina and appearance of age; but do it sparingly

- Top coat - two options

- 2 coats of 2lb cut shellac if not likely to have drinking glass placed on it

- Varnish if more durable finish is needed

- two he likes:

- Waterlox

- General Finishes Arm-R-Seal

- Lacquer is also an option

- After topcoat

- 600 to 1200 grit sandpaper to knock down dust nibs

- rub out with 0000 steel wool until even dull matte appearance

- wipe down with paper towels

- last is dark paste wax - don't use light or it looks bad in the pores

"Create an Aged Arts-and-Crafts Finish.pdf" 2007 [part of "18 Bookcase plans"] article references FWW 157 July 2002

p42

finishing white oak youtube video

"Arts & Crafts Finish" PWW June 2002 pdfp57 Stickley finish for mission furniture without fuming by Chris Schwarz

- wait a couple days between each step for everything to dry

- dye oak red, then put a chocolate brown stain over it

- random orbit sanders leve little "pig tails" in the ray flake that will collect pigment, as will the marks from a smoothing plane

- he sands to 180 grit [with random orbit sander?], then 220 grit on sanding block and 5 to 6 passes over each area with the grain, blow out with compressed air

- he likes J.E Moser's aniline dyes - in particular Golden Amber Maple color

- water-based product is much more fade resistant but before use need to wet product with water and hand sand to 220 grit

- he thinks powder is too strong at mfg suggested 1oz podwer with 1 quart water so he only uses 1/2oz

- apply dye with spong, rag or disposable paint brush

- flood a surface and immediately remove excess with rag

- if overlap marks, when dry they won't show much. also, next step of using a glaze as a stain will help

- he doesn't add a sealer between dye and glaze ???

- Glaze is added over dye then topcoated again

- glaze can be used to simulate an antique finish by adding years of wear and grime, but he doesn't use it that way

- he uses the glaze like a thick bodied stain

- was Guardsman brand, then Lilly then Valspar

- didn't add the rest of the article to this .html as I couldn't find the glaze he used

- topcoat over glaze- finish with lacquer or shellac

- for small projects, use aerosol cans of lacquer (you can buy it at home center stores. If it states it dries in 30 minutes it is probably lacquer

- for larger projects, use aerosol cans of lacquer for first sealer coat then topcoat with whichever brushed on finish you like

- don't apply sealer coat with rag

- don't apply an oil finish

- sand after first sealer coat and between coats.

- he likes to spray three thin coats of lacquer

Arts & Crafts recipe dye + stain together

FWW 0182 pdfp47

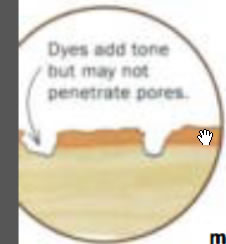

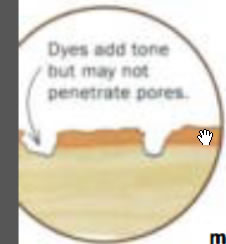

- DYES DISPLAY FIGURE

molecular size particles that attach themselves to wood fibers;

essentially transparent;

can add a lot of color without grain definition loss

dye molecules stay in solution an don't settle to the bottom

enhance figure and make wood shimmer (chatoyance)

on highly figured woods like curly maple, get 3d look

can cause bad blotching on pine and cherry;

can leave open pored speciies like oak looking off white

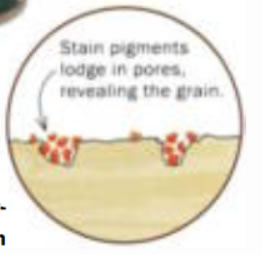

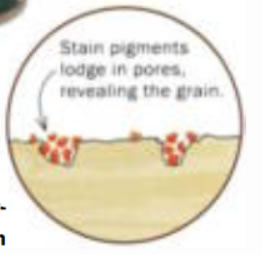

- STAINS ENHANCE GRAIN

colored pigments with a binder (oil, varnish or acrylic which is water based) in liquid or gel form that glues them to the wood

lodge in grain and pore structure which makes them a good choice for open pore woods like ash and oak

on tight grained woods such as maple most of the color is wiped off when the excess is removed

will lodge in scratches, tearout and gouges

multiple coats become more like paint

binder isn't bery strong so multiple coats become a weak link in the finish

- pop the curl in curly maple, enhance the rays of quartersawn white oak, give fresh-cut, pallid cherrty the deep glow of an 18th century antique

- brighter dye colors such as golden brown, red, yellow, amber and orange create highlights that will transmit through a wide variety of stains

- stain adds color and defines the grain and pore structure

- when a stain is applied over a coat of clear finish (e.g. Dewaxed Shellac which is ideal for this) it is known as a glaze.

First apply a washcoat to seal the wood to prevent stain from penetrating it (possibly causing blotching).

Use 1/2 lb. cut on woods with a fine pore and grin structure in combination with a thick oil-based glaze.

For a waterbased or thin oil based glaze a 1lb cut helps prevent blotching.

1lb cut also good for wood with larger pores, perhaps applying a second coat to further limit how much color the glaze will add.

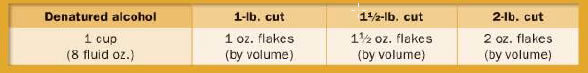

- For Zinsser's SealCoat (which is premixed dewaxed shellac), dilute it with denatured alcohol in a 1:1 ratio for a 1lb cut or 2:1 ratio for 1/2 lb cut

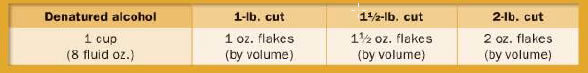

- From shellac flakes, a 1-lb cut is about 10% flakes by volume. e.g. to make 8oz of 1lb cut shellac, pour 7.2 oz of alcohol into a measuring container and add flakes until the level reachs 8 oz.

- to find dye color he likes, he starts with 1/2oz dye and 16oz solvent put sample on board

thin it with equal parts solvent put sample on board

thin it with two parts solvent to one part dye put sample on board

thin it 4:1 ratio solvent to dye put sample on board

maybe even thin it to 8:1 rato and put sample on board

Wood magazine article "Arts & Crafts Finish Without the Fumes" (local .pdf)

woodsmith 179 pdfp33 making a leg with veneer on 2 sides

Arts & Crafts fuming with Ammonia FWW 0126 pdfp46

Arts & Crafts fumed finish FWW 0186 pdfp116 p116

Brushes

2009 January AMWW pdfp63 Brush on Finish the easy way by S. Lloyd Natof

workbench 301 pdfp24 - when soaking a brush, keep bristles off the bottom by pinching the ferrule between 2 sticks held by spring clamp

FWW 0180 pdfp110 Caring for brushes

AMWW Nov 2012 pdfp10 put a rubber glove from tips towards handle and secure with rubber band to get 24 hours before cleaning

wooster on selecting a brush:

Water based:

- Synthetic brushes are recommended for latex and acrylic paints and water-based wood finishes

. Synthetic brushes are available in a variety of filaments including Chinex®, nylon, nylon/polyester blend and polyester.

- Chinex® brushes are the most durable and will maintain their stiffness for control even when exposed to heat and humidity.

- Nylon brushes are very durable but will soften in hot weather or after prolonged use in latex paint.

- Polyester brushes will maintain their shape and control when exposed to heat but have lower paint pick up and production meaning you will spend more time loading your brush.

- A nylon/polyester blend brush combines all the positive qualities of nylon (precise tipping, excellent paint pick up and smooth finish) and polyester (added stiffness and control) and is the most popular professional paintbrush choice due to their all-around versatility (today’s paints contain more acrylic resins and fast-drying solids which stick to polyester making them difficult to clean and limit the life of the brush)

Oil Based:

- Natural bristle is the best choice for oil-based paints, varnishes, shellac, alkyd enamels, oil stains and oil-based polyurethanes

- If you’re painting a smooth surface, use a White China Bristle for a super-smooth finish. points to "Pro Classic" with white bristles that lists Oil-Based Paints, Stains, Polyurethanes & Varnishes" and "Great in Interior Applications"

- When painting a textured surface, a Black China Bristle will work best because it’s slightly stiffer, more durable, and is excellent for high-productivity applications. points to "Pro Classic" with black bristles that lists "Oil-Based Paints & Stains" only and "Great for Exterior Applications"

- don't use natural as rough surface breaks tips off natural ( synthetic, nylon brush is best for this application even when using oil-based coatings because of its high durability and resistance to wear on rough surfaces

per this page

Chinex® is a modified nylon bristle developed by the Dupont company and used by many brush manufacturers as an alternative to natural bristle brushes for oil-based and latex paint. It has similar performance to China bristle but cleans-up faster and easier, has longer brush-life, and holds it's shape and stiffness better.

it appears that the advice from guy at hartville paint dept was wrong

he said

"for oil based urethane use chinex (which i bought)"; this appears to be synthetic but check actual package; maybe ok because it mimics natural china bristle?

he also said "for waterbased poly brush use one any paints labelled" which appears to be correct

another page on natural vs synthetic

a post in this thread on chinex vs nylon/polyester claims

As a general rule, with the more expensive, thicker paints you might like the Chinex better, and with thinner paints you might like the nylon/poly blend better. It's not really a huge deal either way.

The Minwax Oil-Based Topcoat Brush 2" White Bristle Blend 7 16341 00869 7 appers to now be labelled "Fast Drying Polyurethane Brush" as it has the same SKU

"natural bristle brush specifically designed for use with oil-based clear finishing products"

the one i got has "White Bristle Blend" label, but has black bristles; the one in same SKU link has white bristles; did someone put it in the wrong package?

Wooster Alph 2" Firm #4231 07149716600 5

ALPHA® Highest Production Holds More, Paints More MAX PRODUCTION • All Paints • Excels in High-Sheen Applications • Firm, Proprietary Filament Blend

other Wooster models:

Chinex FTP "easiest to clean, Most Durable with Excellent Cleanability EASIEST TO CLEAN • All Paints & Stains • Ideal for Fast-Drying & Low VOC Coatings • Extra-Firm Mix of 100% Chinex® Filaments

ULTRA/PRO® For Fine Finishes Durable & Easy to Clean SMOOTH FINISH • All Paints • Superior Performance in Low Humidity & Cooler Temps • Soft Blend of 100% Nylon Filament

ULTRA/PRO® All-Around Versatility Precise Control + Everyday Durability COMPLETE PERFORMANCE • All Paints • Great for Both Indoor & Outdoor Applications • Firm Mix of Nylon & Polyester Filaments

ULTRA/PRO® Ultimate Control for Easier Cuts & Sharp Lines MAX CONTROL • All Paints • Maintains Control Even in Hot/Humid Conditions • Extra-Firm Blend of Wooster-Exclusive NylonPlus™ & Nylon Filaments

GOLD EDGE® Faster Application Great Production, Great Control HIGH PRODUCTION • All Paints • Easily Applies Thicker-Bodied Coatings • Firm Blend of 100% CT Polyester Filaments

SILVER TIP® Smooth Finish with Great Coverage SMOOTHEST FINISH • All Paints • Virtually Eliminates Brush Marks • Soft Blend of 100% CT™ Polyester Filaments

SUPER/PRO™ Pro Performance Production + Control ALL-PURPOSE • All Paints • Great in All Climates, Indoors & Outdoors • Firm Blend of Nylon & Polyester Filament

PRODUCTION PAINTER™ Quick Coverage, Quick Cleanup FAST COVERAGE • All Paints • Durable for Both Interior & Exterior Applications • Firm Blend of Nylon & Polyester Filaments

PRO CLASSIC® Oil-Based Coatings Coverage & Durability for Rough Surfaces FOR ROUGH APPLICATIONS BLACK CHINA BRISTLE • Oil-Based Paints & Stains • Great for Exterior Applications • Firm Blend of Black China Bristle

WHITE CHINA PRO CLASSIC BRISTLE ® Oil-Based Coatings Good Coverage for Fine Finishes FOR SMOOTH APPLICATIONS • Oil-Based Paints, Stains, Polyurethanes & Varnishes • Great for Interior Applications • Soft Blend of White China Bristle

YACHTSMAN SMOOTHEST FINISH ® SMOOTHEST FINISH • Oil-Based Paints, Stains, Polyurethanes & Varnishes • Soft Blend of White China Bristle

SOFTIP® SMOOTH FINISH • All Paints • Soft Polyester Blend

AMBER FONG SMOOTH FINISH ® SMOOTH FINISH • All Oil-Based Enamels, Varnishes and Stains • Soft Brown China Bristle

per this Minwax blog entry

stain can be applied with a rag or brush; brush gets into corners better but quality not important since wipe off excess with rag

for water-based stains and clear finishes don't use a natural bristle brush as it can absorb water and lose its shape

storing just cleaned brush: After cleaning, wrap the damp bristles in a paper towel, then secure with a rubber band. Once the bristles are dry, slip your brush back into its cardboard sleeve to maintain their shape.

Cherry

2025-07 PWW Easy Aged Cherry Finish

General Finishes Gel Topcoat clear urethane finish, two coats

General Finishes Candelite gel stain

Gel Topcoat: Oil Based Urethane | General Finishes

Add age to cherry FWW 0267 pdfp61

PWW How to stain cherry without blotching

Dyes

2025-05 old link to Homestead Finishing Products in Cleveland area selling luthier finishing stuff and maker of transtint dies

Making Sense of Dyes PW Nov 2006 pdfp62

the impact of light on dyes and stains FWW 0187 pdfp120

Dye Stains "Colors to Dye For" PWW 2003-04 pdfp69

.xlsx for partial ounce batches showing ounces of water to drops of dye

how long do mixed dyes last

FWW 0238 p84 stored in a jelly jar out of strong light, mixed dyes remain good for years.

Finishing both sides

Flexner on why it isn't necessary PWW Oct 2004 pdfp85

Gel varnish

Popular Woodworking Dec 2009 p 74

- oil/varnish bled is a thinned mixture of boiled linseed oil or tung oil with alkyd or polyurethane varnish ; mix one part oil, one part varnish and one part mineral spirits; gives satin or "rubbed" finish but not water resistant because too thin as all coats must be wiped off or the finish dries sticky; to repair just add another coat

- wiping varnish is

alkyd or polyurethane varnish thinned a quarter to a half with mineral spirits to make it easy to wipe on and off; can be left thicker because it dries hard; can be built up for water resistance; dries gloss but can rub final coat with fine steel wool ;to repair just add another coat

- gel varnish is compromise of the two; gel stain without pigment; no need to let it sit on wood before wiping off because it doesn't soak into wood; dries more quickly than the others; just as with any finish, sand after every coat with 320 to 400 grit "stearated" sandpaper. can get satin sheen with four coats but water resistance takes "a great many coats"; can apply 2 or 3 coats per day; for quicker water resistance, do several coats of wiping varnish leaving most or all of the excess to build a thickness then 2 coats of gel varnish then 000 or 0000 steel wool to get satin finish; use a throw away chip brush to apply to corners and a dry one to remove from corners; to repair just add another coat

The Many Faces of Varnish PWW 2005-06 pdfp73 p90

"Gel varnish is very popular with amateurs because, like wiping varnish, it can be appplied to produce a smooth, ridge-ree results without an expensive spray gun."

2024-12 "A Fabulous Brush-On / Wipe-On Finish" by S. Loyd Natof

Bartley's Gel Varnish over Minwax Fast Drying Polyurethane with many hints on edges, inside, etc.

inside of a drawer finishing

fww 0222 pdfp88

if inside is finished, wood's seasonal movement nicluding summer swelling is reduced, so in summer less likely drawer will bind

use low odor finish = 3 thin coats shellac or 3 thin coats lacquer or 1 coat waterbourne finishes

do not use oil based finish as lack of oxygen will cause it to never fully cure and always smell bad

in the photo is shellac in a cloth folded into U shape somewhat similar to a flattened french polish rag.

finishing a drawer FWW 0189 pdfp108

Lacquer

FWW 0182 pdfp102 how to brush on a lacquer finish

advantage is repair by just putting on another coat

brushing lacquer FWW 0182 pdfp102

different types of lacquer explained by Flexner PWW Apr 2010 pdfp56 p54

- many different kinds

- lacquer thinner make lacquer dry much faster so it is resistant to runs and sags on vertical surfaces because it begins to dry between the gun and surface

- among the several kinds is CAB-acrylic lacquer which is clear and a good choice for light woods like maple

- water based lacquer isn't really lacquer, not a good choice as it raises grain and since there is no lacquer thinner they run and sag

Maple

Pop the figure in maple FWW 0267 pdfp60

misc

2025-09 Stumpy Nubs on getting a smooth finish

1 coat finish, then sand to 320 grit

vacuum, then wipe down with mineral spirits or denatured alcohol

then 600 grit

he uses thin coats starting on the second coat so it dries faster

he uses 1000 to 1500 grit to buff out final coat, brown paper bag works about just as good

PWW using 1" & 1 1/4" pipe to make a turntable

video using tape as a funnel leaving tabs long to form spout

2025-05 Make Something youtube channel "My New Favorite Finish. Easy, Cheap and Impossible to Mess Up!"

- sand to 220 grit

- apply zinser shellac full strength with foam brush, wait ~15 mins

- sand very lightly with 220 grit, wait ~15 mins

- thin shellac some and recoat

- sand very lightly with 220 grit, wait ~15 mins

- buff with red scotchbrite pad under random orbit sander then same with grey scotchbrite pad

- thin shellac some apply with paper towel, wait ~15 mins

- and very lightly with 220 grit, wait ~15 mins

- buff with red scotchbrite pad under random orbit sander then same with grey scotchbrite pad then same with white scotchbrite pad

- heavy coat of clear briwax with cloth

- cut out section of tshirt, put under random orbit sander and buff

2024-12 "A Fabulous Brush-On / Wipe-On Finish" by S. Loyd Natof

Bartley's Gel Varnish over Minwax Fast Drying Polyurethane with many hints on edges, inside, etc.

blog posts from rpwoodwork that details his favorite finishes ( the "wear bevel" ruler trick posts from same guy)

PWW video Perfect Painted Finish with Durhams Water Putty

example is an mdf tool stand to seal edges

takes paint well and sands well

only mix what can be used in a few minutes - he likes thick pancake batter consistency

make sure no voids (e.g. when filling screw hole)

expands slighty when it dries

non-toxic, so sometimes easier to apply with finger

turns white as it dries

harder than mdf or hardwood it was applied to, so use hand sanding block and feather out edges like when doing drywall

he brushes sandpaper with brass brush to remove clogging

make sure to use "high build primer" or "high hiding primer" e.g. Zinser 123

he applies primer with 4" foam roller or sprays it

another shorter video about adding pigment since it won't take stain (though it does take paint)

woodsmith article on Creating smooth surfaces with Durhan's Rock Hard Water Putty

Flexner's 12 tips Am Woodworker 2007-01 pdfp43

2 clean varnish brushes mineral spirits, then lacquer thinner then soap and water

7 find dried glue before finishing - before final sanding using water or (if ventilation) mineral spirits & how to remove

9 sand more on end grain

10 reduce blotching on pine

11 let wood conditioners used to reduce blotching dry overnight

12 thin finishes for better leveling reducing brush marks when brushing and orange peel when spraying

before finishing, rub chalk on side on workpiece to make milling marks easier to see Am. Woodworker "September, 2008.pdf" pdfp6

Problems in Wood Finishing | Popular Woodworking

Make Your Own Stain Marker | Popular Woodworking

The Choice You Finish With by Paul Sellers

using a rubber glove to preserve finish overnight .jpg

using a nylon rather than cotton finishing pad .jpg

fww 0267 pdp55 Four great finishes with hardware store supplies for maple, walnut, cherry, mahogany

fine woodworking.com finishing techniques

grain filler for mirror finishes FWW 0253 p39

must color "neutral" or "natural" woodfillers to match the workpiece

tipping off is making the last brush strokes with the brush at 90 degrees to the finish

finishing supplies from Cleveland company maybe mail order only Homestead Finishing Products seem to make Transtint I bought at Woodcraft

caring for furniture (waxes and polishes) PWW Feb 2002 pdfp78

Applying Wiping Varnish everything "Popular Woodworking November 2008" p90 pdfp.84

The Basics of Wiping Varnish PWW 2005-11 pdfp 47 p70

varnish on a butcher block varnish butcher block everything "Popular Woodworking November 2008" p.30 pdfp.15

Finishing the 5 types of wood by Flexner April_2009_PW.pdf pdfp66

- pine & softwoods

- fine grained woods: many blotch, sometimes that is desireable (e.g. bird's eye or curly maple). reduce blotching with washcoat (thinned finish) before stain. use any type of finish, oil finishes require many coats. use water based on white woods as they have no yellowing, but that makes cherry washed out unless stain under finish.

- medium grained woods - eg. mahogany & walnut, finish to look the most elegant of all woods as long as the pores are filled; if using water based apply stain under the finish

- coarse grained woods

- only quartersawn oak looks good with pores filled; water soluble dye stains don't color the pores well. if you use a water dye, follow it with an oil-based wiping stain of a similar color either directly over the dye or over a washcoat to add color to the pores

- exotic woods

Solvents & Thinners PWW April 2002 pdfp72

Master the Wipe-on Finish PWW 2004-08 pdfp73 p 86

Finish Thickness PWW 2006-12 pdfp71 p98

Rub To Create a Great Finish PWW 2006-08:

Finishing using products from a hardware store by Flexner PWW Nov 2007 pdfp64 p96

pdfp 66 - to eliminate brush strokes, thin the finish 1/4 to 1/2 with the appropriate thinner.

oil finishes PWW 2006-04 p90

Wood Conditioners PWW 2005-10 pdfp85 p110

The Basics of Wiping Varnish PWW 2005-11 pdfp47 p70

Pros and Cons of Oil Finishes FWW 177 pdfp22

Flexner on Fine Sanding Myths (local .pdf)

When to stop sanding before finsihing FWW 0189 pdfp45

put

the sandpaper down after using P150-grit if using a film finish, P220-grit for an oil finish on non-blotchy wood, and probably P400-grit on blotch-prone boards.

if staining before finishing, do testing. generally higher grit reduces stain absorption.

kitchen floor finish consider McCloskey Gymseal FWW 0188 pdfp106

Make a spout from tape PWW 260 pdfp11

2023-01-13 At one point I read that a stiff nylon "stripping brush" is good for unclogging sandpaper that is being used between finish coats, so I bought the yellow handled one on amazon

oil finish Glancy's No. 1

Glancy’s No 1 Oil Review | Popular Woodworking

oil finish Tried and True Varnish Oil

FWW 0152 p. 74 boiled linseed oil finish that is actually truly boiled:

Tried and True brand's Varnish Oil

Outdoor finishes

PWW on outdoor finishes and wood choices

Waterproof Outdoor Projects | Popular Woodworking

brush epoxy under spar varnish or similar

FWW 0179 pdfp 42 epoxy sealer and marine varnish

Popular woodworking compares 5 outdoor finish types

Choosing an Exterior Coating PWW 2005-04 p98 pdfp78

Paint

consider buying paint brush cover and outlet cover from here

How do I create a long-lasting, scratch-resistant paint finish?

patching drywall per Sherwin Williams 2022-02-17

- spackle

- mix joint compound with water, then apply over spackle with sponge

- apply very light coat [i wrote down "don't do too heavy" ]

- "only will see it when dry"

- "flashing" is the squares in the dining room where they didn't repaint the entire wall

- in my note i wrote ...patch entire wall... but I think that is inaccurate

Polyurethane

The 7 Myths of Polyurethane by Flexner

Purchases for finishes

2025-01-21 arm-r-seal semi-gloss qt @woodcraft for $38.99 ($46.12 prime at amazon; $37.90+shipping from Infinity Cutting Tools)

Shellac

#application

#Brushing

#French Polish

#pound cuts

#sealer

#spraying

shellac uses denatured alcohol for its solvent

Zinsser Shellac date codes per this post

My A1127-2 shellac is from 2021-01-27

The first number after the letter will be the last digit in the year of manufacture

The second character will correspond to the month; O, N or D for October, November or December, otherwise the single number for the month.

The third and fourth numbers will relate to the actual day of the mo

cool technique mentioned here this old 2009ish video link wireless speaker box

refers to this video on using random orbit sander to buff shellac then wax

pound cuts

pound cuts in smaller quantities

chart to mix pound cuts general info on mixing

chart to change pound cut of already mixed shellac "How to mix Shellac" google cached original article local .pdf with notes to clarify

several articles (including fww 219 pdfp 88) suggest thinning 3lb cut (which is what zinser premixed shellac comes in) 50/50 with denatured alcohol.

according to the chart, this results in ~1 1/4 lb cut

premeasured shellac using postal scale

he uses 1 lb. cut, which is ideal for brushing ultra-smooth coats

1 oz flakes into 8 oz jar and fill with denatured alcohol

for 2 lb cut, use 2oz.; he weighs entire package into 1 oz portions stored in sandwich bags to avoid having to pull out scale so frequently

application

FWW 234 "Make Shellac Your Go-To Finish" pdfp38 by Mario Rodriguez

- stick with dewaxed shellac as it dries hard, cover with wipe-on varnish if durability is desired

- freshness: brush some on some scrap, if still tacky in 2 hours it is too old

- he does 1lb cut for first coat, then 2 coats of 1 1/2 lb cut, then final coat of 1lb

- zinser's SealCoat is dewaxed 2lb cut from store; mix 1 part SealCoat with 1 part alcohol for 1 lb cut; mix 2 parts SealCoat with 1 part alcohol for 1 1/2 lb cut

- sand p120 then p150 then p220; pour on alcohol and wipe down after each

- he coats brush in alcohol then brushes it on as it builds faster than rag application

- [for hard to brush areas, use a pad of wool (others say cheesecloth) in center of lint-free cotton rag; use squeeze bottole to fill center until soaked but not dripping]

- wrap pad so surface is wrinkle free. takes more coats than brushing

- seal pad in glass jar between coats

- lay parts as flat as possible

- edges first, then flat surfaces with long continuos strokes overlapped by 1/4"; start at far corner and work towards yourself

- don't touch up missed spots

- wait 2 hours then sand with p320 to knock down the raised grain; don't use alcohol to remove dust after sanding - use compressed air

- wait ovenight then remove drips with a fresh razor like a card scraper

- rub down with maroon abrasive pad for a matte finish

- wait overnight again then final 1 lb. cul coat and wait overnight again

- for final rubout use superfine (0000) steel wool to knock down the sheen

- if desired, apply oil-based varnish for extra durability

- apply paste wax with cotton t-shirt then buff for a deep, satiny finish

fww 256 pdfp34 p34 "Fast Shellac Finish" by Machael Pekovich

- open pore wood like oak sand to 400 grit

- closed pore wood like maple or cherry sand to 600 grit

- he dilutes Sealcoat 1:1 with denatured alcohol (sealcoat is 2 lb cut from factory, diluting with alcohol 1:1 results in about 1 1/4lb cut)

- after first coat, sand again with previous final grit before shellac first coat

- don't wipe back and forth, wipe it on using straight, slightly operlapping coats and let each coat dry before next

- after shellac application ~4th coat will take 10 mins to cure (while 1 2 3 were pretty much instant)

- sand off any rough areas with 600 grit

- last or next to last step is to buff with steel wool soaked in mineral spirits then charged with paste wax

- for additional protection use wiping varnish - waterlox original sealer / finish (instead of wax?)

- buff with a clean rag

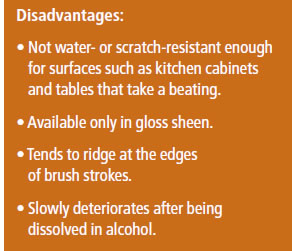

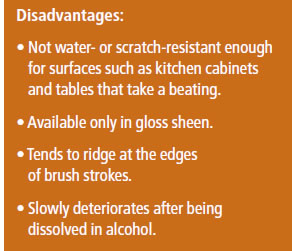

Shellac: A Challenging Finish | Popular Woodworking Flexner 189 April 2011 pdfp60 p58

- "great finish with a great history" but relatively difficult finish to apply

- natural resin is 4 to 5 percent wax

- dewaxed "SealCoat" marketed as a sealer for polyurethane

- even though polyurethane, like all finishes, seals perfectly well on its own

- the need to use shellac as a sealer is way overblown except for some refinishing situations

- There's no noticeable difference when you use the shellac for the entire finish

- pound cut

- 3-pound cut (too thick for brushing without brush marks, so you need to add thinner).

- SealCoat is 2-pound cut (at the upper limit for easy brushing)

- All shellacs are high

gloss

- if scuff to flatten, makes finish very easy to mar (even with back of your fingernail)

- paste wax application makes finish less easy to mar but adds extra work

- Blushing

- when applied in warm humid conditions

- wait for cooler day or add lacquer retarder but test first as some will keep finish from drying

- Ridging at edge of brushstroke

- reduce ridging by thinning more and adding more coats

this thread seems to indicate sand between coats with 320 grit and use mineral spirits to remove dust, then after second to last coat with 400 or 600 mineral spirits to remove dust

one post says after second to last

50% mineral spirts + 50% mineral oil then clean off oil with Naptha

Shellac PWW June 2002 pdfp 60 p76 by Bob Flexner

- primary finish used until 1920s when lacquer was introduced

- 1950s polyurethane and "wiping" varnish (varnish thinned about half with paint thinner and often mislabelled "tung oil")

- 1970s blends of linseed oil and varnish like Watco Danish Oil

- discard shellac 1 year after mixing as it no longer dries properly

- natural orange (warms wood, used on most antiques) and bleached shellac (maintains white color of maple) are the two choices or mix the 2 yourself

- benefits: dries quickly, builds well, easily removed if disaster strikes

- natural shellac is ~5% wax

- dewaxed shellac is more water resistant

- can remove wax from regular shellac by letting it settle then decanting the liquid

- pound cut: 1 lb cut is 1 lb flakes in 1 gallon alchol x lb cut is x lbs flakes in 1 gallon alcohol

- typical premix sold in paint stores is 3 lb cut, which is very thick for brushing or spraying

- for max freshness and therefore hardness, use flakes start with 2lb cut and adjust from there

- brush shellac - work quickly so alchol doesn't all evaporate - use quality natural or synthetic bristle brush or foam brush, wipe with the grain when possible

keep wet edge, wait until next coat if spot was missed if shellac becomes tacky

- thin if spraying to reduce orange peel

- allow first coat to dry 2 hours, sand with gray 320 grit stearated (self lubricated) sandpaper just enough to remove dust nibs and raised grain

use light touch so sandpaper clogs less and so don't go through finish

then remove dust

- for second coat add more alcohol if getting severe brush marks or orange peels or bubbles are drying in the the film

- apply as many coats as you want

- each new coat dissolves into the last so no need to sand between coats except to remove dust nibs and other flaws

- use reflected light to see flaws before they dry and brush them out

- blushing is milky white appearance in the finish from too much humidity or water in alchol or both; tips to fix in article

- if bad problems happen, can always go back to square one by stripping with alchol or paint stripper

- can store brush between coats by hangin it in a jar of alcohol

clean brush with 50/50 mix of household ammonia and water

- can either end with final application or level finish with 320 girt and finer sandpaper and a sanding block

then rub it to the desired sheen with Scotch-Brite, fine steel wool or abrasive compounds (e.g. pumice & rottenstone)

- if the rubbed finish shows finger marks easily, apply paste wax or oily furniture polish

fww 0243 pdfp80 Shellac (e.g. Zinsser Bulls Eye Shellac) vs de-waxed Shellac (e.g. Zinsser Bulls Eye SealCoat)

- both seal but natural wax can interfere with oil-based polyurethan and water based finishes

- can use waxed shellac with nitrocellulose lacquer or oil based varnishes other than polyurethane (such as Waterlox or any alkyd varnish) - use waxy amber or clear 3-lb cut

- if using oil based poly or any water-based finish, stick with dewaxed.

- can mix your own dewaxed using dewaxed shellac flakes - select blond or super blond to avoid darkening the color of the wood

Tips For Using Shellac from PWW (local .pdf)

Thinned Shellac works best

FWW 0219 pdp88 he uses this particular technique on small boxes. it won't build up so quickly and it dries much faster making it easier to get even coats without streaking.

start with 3lb cut, then dilute with equal parts denatured alcohol

apply first coat with cotton pad

after it dries, sand with P600 sandpaper using mineral spirits as lubricant

pad on second coat of shellac and let it dry

buff with 0000 steel wool

apply thin coat of wax and polish with a soft cloth

in less than 30 minutes can apply 2 coats of shellac and coat of waxmineral spirits

fww 0256 pdfp34 Fast Shellac Finish

One Fast Finish - oil, shellac and wax FWW 0186 pdfp52

Sealer

AMWW Jan 2013 pdfp71 using shellac to seal end grain to prevent finish / stain absorption and being to dark

fww 227 p48 use as a sealer

[not sure of source for this info]

If you are finishing a wood with resinous knots (such as pine) or you are refinishing wood with silicone contamination (it causes the finish to roll up in ridges) or animal-urine or smoke orders, use shellac for the sealer coat. Shellac blocks off these problems (but it is not easier to sand). There's no reason to use shellac otherwise.

sand sealer with grit between #220 and #400

in PWW Nov 2007 pdfp67 p99 Flexner states: "The only new-wood use for shellac as a first coat is over serinous knots in softwoods such as pine." He does use it to to combat "fish eye" aka "cratering" when silicone in furniture polish causes refinishing issues with the new finish

shellac as sealer before finishing blotchy woods like cherry FWW 0190 pdfp96

test offcuts with "pure shellac" (what is that?), shellac cut in a 1:1 ratio with denatured alcohol, and one with 1:2 ratio

What is the purpose of waxed shellac thread? Answer appears to be used waxed if it is the final topcoat, use dewaxed if it is a sealer and there is a finish going on top of it. Waxed seems to be easier for French polish, but at least one says they use dewaxed for it.

Sealers and Sealing Wood PWW 2004-06 p86 pdfp73

French Polish / Rubbing out shellac / Padding on shellac

French Polishing Myths | Popular Woodworking

- author's experience is no difference between linen and cotton as long as thin and tightly woven

- trick 1: use mineral oil to see vapor trail

- apply a couple finger dabs of mineral oil to the bottom of the pad every time you add more shellac. Then disperse again (against palm of hand)

- pad is too wet, the vapor trail will be so long that you can’t see it.

- pad is too dry, there won’t be a vapor trail, just an oily smear.

- As you rub, the vapor trail will shorten to only a few inches. This tells you it’s time to replenish the pad.

- second trick is to wipe the oil off the surface now and then with naphtha to see where you are

- third trick is to reduce the amount of shellac and increase the amount of alcohol as you near the end of the job

- that is, as the film starts looking good with the oil removed.

- The easy way to do this is to have one squeeze bottle of two-pound-cut shellac and another of alcohol.

- For all of the building phase, pour some shellac followed by a little alcohol onto the pad and disperse.

- As you near the end, slowly reduce the shellac to nothing, finally adding only alcohol.

- This is to eliminate rag tracks. Just as with brushing, cloths leave tracks, like tiny brush marks, when the finish is thick. Thinning is key to eliminating the rag tracks (and also brush marks).

FRENCH POLISH: SHELLAC, ALCOHOL, OILS & TECHNIQUE

FWW 172 p43 using automotive polishes rather than pumice&rottenstone - followup question on FWW 0176 pdfp95

Fixing Finish With French Polish PWW 2001-11 pdfp77 p102 - describes a compex finish with multiple different layers

padding on shellac fww 0112 pdfp 60

test after 6 months mixed: 2 drops on piece of glass should dry to touch in 5 mins or less

use 100% cotton lint free "padding, trace or French polishing cloth"

he first seals it with boiled linseed oil or tung oil "to give greater depth"

for padding he likes 2lb cut (1/4lb flakes in 1 pint alcohol)

see p62 for hist steps / technique

What is the purpose of waxed shellac thread? Answer appears to be use waxed if it is the final topcoat, use dewaxed if it is a sealer and there is a finish going on top of it. Waxed seems to be easier for French polish, but at least one says they use dewaxed for it.

Rubbing Out Shellac

Wood 290 4 .jpg pages: 1 2 3 4

wood online applying shellac

applicator pad: tightly woven lint free fabric such as an old linen handkerchief or washed t-shirt material

wrap around cotton batting or wool the size of a golf ball

2024-12

this article from homestead finishing is pretty detailed, also claims

"The best cloth for applying shellac is sold as padding, trace or French Polishing Cloth. The best product I’ve used comes in 12″ squares with the edges sewn and has a rumpled texture similar to surgical gauze. Homestead sells the product shown as Padding Cloth." though it appears they don't actually sell it.

Brushing and brush selection

Shopnotes 31 p28

use a natural bristle brush to apply

Brushing Shellac Am Woodworker "September, 2008.pdf" pdfp51

PWW cleaning a shellac brush (local .pdf)

spraying

FWW 227 pdfp85 spraying shellac outdoors since no explosion proof spray booth

- best 55F to 75F with humidity under 70% in shady spot

- don't wan't string winds, but light breeze or box fan will prevent overspray from landing on workpiece

- common problems spraying shellac

1. alcohol is drying too quickly preventing shellac from "flowing out" correctly 2. alcohol is drying too quickly leaving rough or grainy finish because shellac partially dries before it hits the finish

- for both, solution is using denatured alcohol with a low methanol content such as Behlen Bekko which according to this page is now Mohawk Shellac Reducer

- iit and other brands don't have a Poison warning on the can

- A shellac reducer may also help.

solvents

Solvents chart I like is

"spray gun cleaning WWJ April 2003 vol27-2_2 with products" ['Have gun, will Scour by Michael Dresdner]

from Woodworker's Journal April 2003 p28 & 29 p1 p2

Am Woodworker 2007-01 pdfp 43 after cleaning a varnish brush in mineral spirits, don't skip righ to soap and water, faster if use lacquer thinner in between

December_2005_PW_gun_cleaning_p66 .pdf

familyhandyman.com-Mineral Spirits vs Paint Thinner .pdf

gum terpentine thread see Edwin Baker answer

Understanding Lacquer Thinner from PWW

A primer on solvents PWW December_2007 pdfp61

spraying

consider buying General Finishes Brush and Gun Cleaner

2025-12 How To Thin Polyurethane For Spraying | Simple Process| Obsessed Woodworking

2024-09-04ish asked question to sherwin williams about best paint to spray wood trim and wrought iron furniture

white exterior paint - can be sprayed

should i use oil based - not necessarily, they recommneded a water based latex enamel (i think. emerald something)

how many coats & should it need thinned - 2 coats, and it can be thinned (if yes what is thinner - water i think)

proper sized screen - use medium size for the paint they recommend

make sure it is mixed at store

buy caulk for crack at miter

should i caulk between brickmould and j channel - didn't ask , internet sources said no

buy lacquer thinner for wood finish cleanoutxx

caulk and let dry 4 hrs before painting; they recommended caulk for miter and nail holes, I think putty would have been easier to use; also, next time put tape on surface and shoot brad through tape to make cleaning up of nail hole filling easier

they recommended 2 coats 4 hours between

Fine Homebuilding 134 pfp84 Spray Everything

tips for spraying a room, masking, etc.

on trim he does

- "standard resin -based spackling compound",

- sands with 80 grit

- then applies 3m red automtive glazing putty

- sands with 120 grit

- vacuum dust

- wipe with mineral spirits

- left off on pdpf86 "Hauling out the sprayers"

6 Things I Learned from My DIY Home Paint Booth - Hagerty Media

Gun Cleaning

Solvents chart I like is

"spray gun cleaning WWJ April 2003 vol27-2_2 with products" ['Have gun, will Scour by Michael Dresdner]

from Woodworker's Journal April 2003 p28 & 29 p1 p2

How to Clean a Spray Gun PWW 2005-12 pdfp67 great pics for 9 step process (local .pdf of spraying related pages only)

Spray Gun Cleaning Jug | Popular Woodworking

December_2005_PW_gun_cleaning_p66 .pdf

familyhandyman.com-Mineral Spirits vs Paint Thinner .pdf

General spraying information

Finishing Secrets by Woodworker's Journal Winter 2011.pdf p62

highland woodworking beginner's guide to spraying

keep record of viscosity cup times and results so can get best results for your particular gun

cleanup for water based finishes:

Unclip the cup and pull the trigger to drain the pickup tube.

Empty the cup, rinse with clean water, and dump.

Spray fresh water through the gun for 5-10 seconds, again draining the pickup tube when done.

Now spray Brush & Gun Cleaner for a few seconds, wait a few minutes, and spray a few seconds more.

Drain, rinse with water, and flush thoroughly by spraying fresh water for 10-15 seconds.

cleanup for solvent based finishes

clean with appropriate thinner

followed with a rinse with solvent alcohol.

Every now and then you might need to disassemble the gun and soak fluid passages in paint stripper to get everything completely clean.

When switching from one kind of finish to another, rinse with appropriate solvent, wash with soap and water, then rinse with alcohol.

If you see that you've overdosed a water-based finish, grab a wet rag and just wipe it off, then wipe the piece dry and start over.

author likes Hydrocote Exterior Polyshield for spraying: water clear and stays that way, uv protection is for finish only (not underlying wood)

Paul sellers on HVLP for spraying shellac and other finishes (can't adjust pressure at gun) link to system he uses (or closest currently available)

Optimize a Spray Gun | Popular Woodworking

FWW 0248 p54 getting started spraying

Common Spray gun problems and solutions [Popular Woodworing Feb 2006] pdfp 69 p98 (local .pdf spraying pages only)

spray pattern that's heavy at the ends or in the middle

spray pattern heavy at one end

pulsating spray

dripping at the gun

complete cleaning kit [Popular Woodworing Feb 2006] pdfp15 p928

switch to spraying water based finishes fww 0219 pdfpp72

need to have stainless steel or plastic fluid passages and cup (not aluminum)

ok to use stearated sandpaper that used to leavea a waxy coating but process is now improved so it doesn't

for old finishes use shellac sealer coat first to avoid fish-eye caused by silicone and other contaminants

water based doesn't warm the wood which is good for white woods like maple, ash and birch

tips for tinting when

workpiece is cherry walnut or mahogany but water based finishes are milky in can so getting tint correct is tough

using orange or garnet shellac typically works better than tinting

can also use oil on bare wood to enhance figure, then seal with dewaxed shellac before water based finishes

typically dry in 30 to 45 minutes (same as solvent based finishes)

higher solids content means builds a film in fewer coats than solvent based finishes yet water based has excellent 'cling' so fewer runs

put think film of vaseline on the horns of the air cap so buildup can be easily removed

for satin sheen, probably get perfect finish from gun and no need to rub out

for polished out surface, water based won't be as good as solvent lacquer since waterbased's successive coats do not melt completely into previous layer

the non-melting is similar to solvent based varnishes or polyurethanes that build in layers that leave "witness lines' when you polish through one coat into another

solution: apply 3 coats, then completely flatten the surface (making witness lines); now apply more coats and witness lines disappear

wait ~200 hours (~8.5 days) to cure then polish final coat and there is less risk of burning through layers

"for quick drying water based finishes you shouldn't need to sand away dust nibs between coats. however, if you let the finish dry longer than teh time specified on the can, you must sand to give the next coat a mechanical bond"

use a brown paper shopping bag to smooth and polish the last coat of a satin or semi-gloss water based finish.

cleaning gun: after spraying, flush with water and ammonia, then flush it with alcohol or lacquer thinner

General finishes page on "what should I clean my spray gun with"

- for shellac, use denatured alcohol only

- for water based finishes, use a cleaner that is compatible with the product

- rinse with hot water, followed by a cleaning with diluted GF Brush & Gun Cleaner with water to purge residual paint or finish

- dilute Brush and Gun Cleaner up to 50% water

- Use full strength for deep cleaning when switching from stains to clears, or paint to clears

- Use a diluted solution when soaking parts. The soaking mixture is reusable for soaking after use.

- for oil based, use mineral spirits or xylene only

water based finishes and which can be sprayed FWW 0194 pdfp102

compares and gives examples of types Acrylic Blends, Copolymers, Urethanes, Urethane / Acrylic Blends

How long can finish remain in the gun thread

- up to an hour for shellac, but why not just blast solvent (alcohol) through it every time when done

- if breather can be closed has left pre-cat for a couple days before washing but not recommended

- get 2 part finishes out immediately

- use plenty of solvent and don't have to strip down gun for months

- could probably leave shellac in all day

- Jeff Jewitt's new Spray Finishing book and dvd suggest flushing and cleaning water borne finishes after four hours

fww 0194 pdfp60 spray gun choices

turbine's benefit is all included in one purchase, less capable than compressor or compressor with pressure pot

gravity gun that i have will not sputter when empty like a pressured cup under the gun will

pressure pot is probably the best solution

spray finishing made simple wood 262 sept 2019 p58

- "conversion gun" is term they use for separate compressor with gun

- typically 20-30 psi & 5-12 cfm

- claims explosion proof fan is needed to spray shellac with alcohol thinner. Many posts in forums say they do it with regular fan and have never had a problem

- thin water based products with distilled water. often times 5-10% (1 - 1.5 oz per qt) thinning is required, check label

- low angle raking light is helpful

- remove drips and runs with a dry foam brush if done immediately while the finish is wet enough to flow out

- to avoid raising grain, finish sand to 180 or finer, spray 1 or 2 light shellac coats, buff smooth with 320 or finer. if stained, always spray 2 coats to avoid sanding through stain

- to spray water based stain

- sand to 180

- wet wood slightly with sponge

- let dry

- finsh sand again

- apply stain

- let dry

- "if grain raises again, wipe it gently with very fine abrasive and blow away the dust"

- rather than spraying water based stain it is easier to use oil based stain and let it dry 12+ hours until sniffing surface does not smell; then topcoat w water based finish

- FINISH COAT

- spray until wood is fully wet and leaves a bit of stippling or orange-peel immediately after spraying

- DON'T spray until the wet surface is absolutely smooth

- if milky in container and seeing milky on workpiece, using too heavy of a coat

- can wipe off wet finish with wet rag, wipe the piece dry and start over

- in plan view, keep gun travel parallel to surface (not an arc)

- pull trigger before workpiece

- overlap patter about half way to keep a wet edge

- use multiple thin coats

- "move the gun at same speed you would move a brush when "tipping off" a brushed on finish

- for case type projects

- spray interior upright elements

- then interior horizontal elements

- "for removable shelves screw them to supports so you can spray the entire shelf" (see pic p62 - back edge of shelf screwed into foot, spray with shelf vertical)

- for doors, spray outer edges, then rail and stile faces and panel

- as much as possible spray parts in horizontal orientation to avoid drips

- consider leaving back off cabinet so easy access and no bloback in face

- turntable is handy for small projects ( and larger projects can be put on a furniture dolly)

- "with almost any finish you spray, sanding between coats knocks down and dust nibs, making for smoother succeeding coats"

- also helps polyurethane to help new coat link to previous one

- don't stand between project and fan

fww 0169 pdfp117 making a cheap spray booth for water based finishes using foil backed insulation and box fan

above is actual article

reference in 0194 pdfp64 = p64

Specific info for my DeVilbis FLG2

pic of my sprayer is DeVilbiss FLG2 box scan lists model FLG-365-316 aka "Finish Line HVLP Gravity Gun & Cup (#3 -1.6) upc 6 58701 01700 3 "The True 1-Liter Cup"

FLG4 Service manual

see pdfp3 for

air caps chart

fluid tips chart

hvlp air flows

on

DeVilbis FLG2 which fluid nozzle to use

DeVILBISS® StartingLine® 2-Gun HVLP Spray Gun Set aka "2 fi starting line kit" in my google note

Primer gun has 1.8 mm fluid needle/nozzle assembly for heavy or high-build primers.

Finish gun has 1.3 mm fluid nozzle for spraying most automotive finishes and clears and 1.5 mm fluid nozzle for high-solids material. Both have 20-oz aluminum cup.

Not sure FLG generation, but lists these specs

1.3, 1.4, and 1.8 mm fluid nozzles for finishes, clears & primers; 900 ml aluminum cup; and air-adjusting valve. Requires air compressor hookup of 12 cfm @ 26 psi.

2002 DeVilbiss product catalog .pdf doesn't have mine listed but does have many accessories & parts that mine uses

DeVilbiss FLG4 (Finish Line Gun 4) manual I have 2nd version

pdfp4 shows chart with #2 Zahn Cup readings

for mine closest is "Gravity Feed HVLP" = FLG-HVP-315

1.5mm tip

recommended 13cfm at 23psi

for "Heavy" Material (over 30 secs in #2 zahn cup) there are checks for Enamels and Polyurethane but not Latex nor Contact Adhesives

for "Medium" Material (over 19-30 secs in #2 zahn cup) there are checks for all 4: Epoxies, Varnishes, Thinned Latex and Topcoat Lacquer

for "Light" Material (14-20 secs in #2 zahn cup) there are checks for all 4: Sealers, Wash Primers, Stain, Nitro Lacquer

[

this post indicates

'Lacquer' doesn't necessarily mean 'nitro'. It's just another name for a clear coat. It could be nitro, poly, acrylic, nail polish or hair lacquer.]

p2 shows conventional is better than hvlp for higher viscosity materials since greater pressure of 30-50psi as opposed to ~10psi or less for hvlp

Zahn cup

zahn cup to measure viscosity instructions for mine front back shipping lable

Staining

PWW AUG 2009 pdfp57 Flexner: Wipe Don't Brush [Stains]

gel finish dry times, specifically for the Candlelite Gel Stain from General Finishes that I have

Understanding Wood Finishing - Oil, Film Building, Stains, Solvents

How to Choose a finish (local .pdf)

PWW 222 Dec 2015 pdfp56

- Oil Finishes - typically boiled linseed oil or tung oil

- easy to apply - apply a wet coat, wait a few minutes, wipe off all excess

- tung oil wrinkles when it dries even with the excess removed. to get a smooth result apply 5 or more coats, sanding smooth and allowing 2-3 days to dry betwen each

- boiled linseed oil can be applied every day and the results are always smooth when the excess is wiped off; 2 or3 coats is usually enough per this PWW article; sanding only is needed after the first coat

- both can be combined with alkyd or polyurethane varnish in any proportion to make an oil varnish blend. this makes a little harder and a little more water resistant than straight oil, but just by a small amount because such a thin application

- boiled linseed

oil yellows more than tung oil per this PWW article

- per this PWW article Tung oil is more water resistant than linseed oil because it has approximately three crosslinks between molecules instead of the slightly less than two for linseed oil. But because neither oil hardens well so neither can be built up thick, both are less water resistant than a built-up alkyd or polyurethane varnish, lacquer, shellac or water-based finish.

- per this PWW article with tung oil many products are labeled “tung oil” when they are actually varnish thinned about half with mineral spirits (paint thinner). It makes no difference whether the varnish was made with tung oil; it’s still varnish. It dries hard and can be built up. You can identify these by reading the fine print on the label, which will list a thinner: “contains petroleum distillates,” “contains mineral spirits,” “contains aliphatic hydrocarbons,” which are different names for the same thing. Real tung oil is usually labeled 100% tung oil and never contains a thinner.

- Film Building Finishes

- varnish, water based finish, shellac, lacquer and catalized finishes; all dry hard so they can be built up to a very liquid resistant film

- can be thinned as much as desired but takes more coats

- varnish is often thinned about half with mineral spirits and sold as oil (this causes a lot of confusion) but it is still varnish so it can be built up

- 3 categories based on how they dry (all can be applied with any finish application tool):

- reactive finishes are like tinker toys at molecular level; e.g. varnish (cross linked by exposure to air) and catalyzed finishes (cross linked with aid of catalyst) ; hard, heat and solvent resistant film because crosslinking is so strong; varnish dries slowly while catalyzed finishes dry quickly like lacquer.

- evaporative finishs are like spaghetti in a pot; e.g. shellac and lacquer; dry by evaporation of the solvent leaving tangled hard molecules like dry spaghetti in a pot; dry fast but more vulnerable to wear, heat and solvent damage than reactive finishes because no strong cross linking between molecules but easier to repair invisibly with the aid of heat or solvent and easier to rub to an even sheen because the molecules can be separated so easily with abrasives.

- coalescing finshes are like soccer balls with solid crosslinked cores; e..g water based finishes; dry by evaporation of water then the evaporation of the solvent like soccer balls stuck together; in betwen reactive and eavporative in speed of drying; similar to reactive in scratch resistance but vulnerable to heat and solvent damage; raise the grain of wood, dry totally colorless; less irritating when applying

- Stains

- use two colorants

- pigment = solid colorant ground very fine that settles to the bottom and must be stirred into suspension before use

- dye = colorant that dissolves in a liquid

- category 1 = "binder stains"

- common stains found in stores with binder of linseed oil, varnish, lacquer or water-based finish

- can contain just pigment, just dye or both

- limits ability to make darker as the excess is wiped off

- category 2 = "dye stains"

- a) water-soluable powders or alcohol-soluable powders that you dissolve yourself in the proper solvent

- b) metal-complex dyes that are typically already disolved. some are sold as concentrates that you thin with water, alcohol, acetone or lacquer thinner; others are already thinned with acetone ready for spraying. more uv light resistant than water powder dyes but "not significant on any object you want to last for more than a few years"

- dye stains can color wood as dark as you want by using more coats or higher concentration of dye

- both types should be kept out of sunlight or they will fade.

- Solvents:

- oil and varnish use mineral spirits (paint thinner) or naptha (which evaporates faster)

- shellac uses denatured alcohol

- lacquer and most catalyzed finishes use lacquer thinner or acetone (which evaporates faster)

- water base finishes use water

Varnish

"Wiping Varnish: The only Finish You'll Ever Need" - FWW 0218 pdfp49

The Many Faces of Varnish PWW 2005-06 pdfp73 p90

"Gel varnish is very popular with amateurs because, like wiping varnish, it can be appplied to produce a smooth, ridge-free results without an expensive spray gun."

Varnish definition

- combination of a hard resin {alkyd, polyurethane, phenolic} with an oil {linseed oil, tung oil, modified soybean oil, modified soybean oil}

then cooked

- if product thins with mineral spirts (aka "petroleum distillate") and cures hard then it is varnish

- note: linseed oil, tung oil and blends of varnish and oil do thin with mineral but they dry soft

- to test, pour puddle on non-pourous surface

- if it wrinkles when it cures it is not varnish

There are 8 categories of Varnish

| |

|

example products |

| alkyd varnish |

- the common varnish at hardware stores

- interior only

- made with alkyd resin cooked with one or more oils

|

McCloskey Heirloom Clear Varnish |

| polyurethane |

- made with both alkyd and polyurethane resins (called "uralkyd")

- typically uses modified soybean oil to minimize yellowing

- more durable than varnish

- this industrial floor mfg and this plastic parts maker both claim there is no difference between polyurethane and urethane

|

Minwax Fast-Drying Polurethane

Defthane

Varathane |

| spar varnish |

- exterior

- higher ratio of oil to resin than interior varnish

- makes it more flexible to withstand the greater wood movement of the outdoors

- often made with phenoilc or polyurethane resin and tung oil for best water resistance

- dfdhttps://www.boatdesign.net/threads/urethane-vs-varnish.13461/#post-516740

|

McCloskey Man O' War Marine Spar Varnish |

| marine (boat) varnish |

- spar varnish with UV light absorbers

- this thread on urethane vs varnish seems to love System 3 Marine Coatings WR-LPU two part polyurethane topcoat which is water based

- claims linseed oil based products blacken with time and exposure

- marine spar urethanes are harder, glossier and more durable than spar varnish's typical alkyd varnish formulations but they are tough to repair

- more traditional alkyd varnishes are far easier to repair if necessary, but aren't as durable as the harder LPU's

|

Epifanes Clear Varnish with extra UV filter

interestingly the article picture shows W. Heeren & Zn Epifanes Boolak which mfg lists as paint made from Linseed oil / alkyd resin and is sold as "Yacht enamel" in the US and is colored

same Dutch mfg as West Marine expoxy

this page says

In the broadest sense, enamel paint means any solvent-based (aka "oil-based") paint that dries to a hard, vitreous-like (or, glass-like) shell |

| wiping varnish |

- Fetzner's term

- typically alkyd resin (though sometimes polyurethane) with one of the oils

- "Waterlox" uses phenoic resin and one of the oils

- thinned heavliy with with mineral spirits

- make your own with any of the above 4 varnishes

- per this post about Arm-R-Seal

- Satin finish is achieved by adding flatting agent to gloss version of ARS. Use of flattening agents in thick top coat can make finish cloudy, and obscure grain. If you want a thick film build applied by wiping on many layers of ARS; it is recommended that you use gloss version for all, but top 1~2 coats

|

General Finshes Arm-R-Seal urethane Sealer (3 sheens)

General Finishes Seal-A-Cell not a topcoat, has wax, most pentrating GF finish; used to highlight grain (presumably if not staining?); cover with any of the other 3 GFs

many other brands |

| salad bowl finish |

- wiping varnish with marketting name

- all varnishes and wiping varnishes are safe after they have cured

|

General Finishes Salad Bowl Finish

very thin, gloss only |

| wood conditioner |

- aka "stain controller"

- prevents blotching

- alkyd varnish with soybean oil thinned to about 2 parts mineral spirits to one part varnish

- used as a "washcoat"

- often instructions on can are incorrect: it actually needs to cure to prevent stain from penetrating so let it dry overnight first

|

|

| gel varnish |

- see gel varnish section above

- typically made with alkyd resin and one of the oils but sometimes uses polyurethane resin

- given a thixotropic quality like mayonaise or latex wall paint

- idea is that it is easy to wipe on since no drips or runs

- you have to wipe off most of the exces to avoid severe ridging

- "Gel varnish is very popular with amateurs because, like wiping varnish, it can be appplied to produce a smooth, ridge-free results without an expensive spray gun."

|

General Finishes Gel Topcoat thicker than Arm-R-Seal satin only urethane; I bought this [arm-r-seal i think] 2024-04

Gel Topcoat: Oil Based Urethane | General Finishes i bought this 2025-07ish

Bartley Gel Varnish |

Water based finishes

much information in spraying and elsewhere

fww 0194 pdfp103

- best brushed on with fine-haired, artificial bristle artist's brush. Larger, denser brushes introduce too much air into the finish leaving bubbles

- pic shows ~2" wide brush (not typical artist shaped round handle brush)

- "use fine arts and special purpose brushes that feature shorter bristles and a thin nap

- da Vinci's cosmotop and top-acyrl series

- winsor and newtons athena and monarch series

- purdy's syntox brushes

- typically use 1" to 3 1/2" wide brush

- can typically sand within an hour and recoat with 24 hours, but check can

- in general, water based has primary glycol solvent to dissolve the resin allowing it to form a crude film, and water acts as secondary solvent (aka diluent) that evaporates with the glycol as the film dries

- water borne

- water reducible

Water Damage Repair

PWW on Repair Water Damaged Wood by Kevin Southwick

use Oxalic Acid

(local.pdf)

Wax

All about Wax FWW 0191 June 2007 pdfp54

The Facts On Wax - poor finish but excellent polish PWW 2004-02 pdfp76 p100

Wipe-on Finishes

boiled linseed oil per Highland Hardware [part of this article on home made finishes]

- can be used either alone or with other oil finishes and solvents

- also used as an additive to oil-based paints, stains and varnishes to improve brushing and flow characteristics

- suitable wipe-on finish for your interior wood furniture projects and workbenches

- crafting your own blend for a wipe-on, "varn-oil finish" by mixing it with spar varnish and mineral spirits.

- Danish furniture maker Tage Frid would use 1 part linseed oil, 2 parts varnish and 3 parts mineral spirits, but you can experiment with your own ratios.

- DIY polyurethane furniture finish recipe from Chris Swartz as described by Anne of All Trades

- Boiled Linseed Oil

- (Jasco is a good brand)

- oils and protects the furniture and gives it a beautiful glow. It does not, however, harden well, which is the job of the polyurethane

- Oil based Polyurethane

- ( Helmsman Indoor/Outdoor Spar Urethane is a good brand)

- clear satin spar varnish still adds a warm amber hue, and I love it because I don't want the finish to be super shiny which requires quite a bit of sanding to cover flaws left behind

- don't use water based

- Mineral Spirits

- (Jasco Odorless Mineral Spirits is a good brand)

- wipe on a generous initial coat, rub it in, but MAKE SURE to rub off ALL the excess (all the shiny spots) with a dry tshirt before that 30 minute mark

- Let dry 24 hours between coats

- see Step by Step Instructions

- give plenty of finish to the wood (applying thin coats is not necessary)

- stop around two or three coats

- the Highland Article mentions making varnish itself out of sandarac, which appears to be a natural resin like pine pitch

Seal-Cell & Arm-R-Seal wipe on finish from this thread

- Flood surface with seal a cell.

- Wipe off after a few minutes and let dry

- rub with 0000 steel wool

- blow off or wipe off dust

- Wipe on General finishes Arm-R-Seal -- Gloss

- wipe off after a few minutes

- rub with 0000 steel wool

- blow off or wipe off dust

- Repeat the Arm-R-Seal step a few times util you are happy

- Finally-- Rub with 0000 steel wool and paste wax if you want to bring the finish down to a nice satin look. This finish looks and feels great.

FWW0178 p32 Wipe-On Finish Test

- aka Danish oils -mix of varnish resing, solvents, chemical driers, and linseed or tung oils

- easy application, quick drying time, good protection

- specifically Tried & True Varnish Oil he found difficult to wipe on and off, hard to apply an even coat & was still wet after 30 days; ranked worst

- one of the samples was Minwax Fast-Drying Polyurethane Varnish, which I think was rebranded and is now sold at

The Confusion Surrounding Wipe-on Finishes by Bob Flexner

- 4 types

- oil

- excess has to be wiped off

- tung oil is more water resistent than linseed oil and and replaced linseed oil around the turn of the 20th century as the oil ingredient in exterior varnishes

- tung oil dries considerably slower than boiled linseed oil,

- it doesn't look or feel nice until five or more coats are applied and sanded between each,

- and it never gets hard, so no build can be achieved.

- Tung oil is not used very often as a finish.

- wiping varnish (alkyd or polyurethane varnish thinned about half with mineral spirits)

- can be wiped off, or it can be left damp or wet on the wood to build faster because it dries hard.

- oil varnish blends

- excess has to be wiped off

- gel varnish

- dries hard, but wipe off so don't get streaks

- Each of these finishes can be wiped or brushed, or even sprayed, on the wood and then wiped off.

- manufacturers began selling thinned varnish and oil/varnish blends and calling the product “tung oil.”

- Varnish is made by cooking oil with a resin, including synthetic alkyd and polyurethane resins. This changes the chemistry, causing the finish to dry hard.

Hod-Rod Your Varnish FWW 0198 pdp74 home made oil varnish blend recipe

- recipe

- 5 parts pratt & lambert no 38 alky varnish

- 5 pars pure tung oil for water resistance

- 2 parts Japan Drier to speed drying time

- 2 to 3 parts pure gum spirits turpentine to make wiping easier

- beneftis

- applies easily by hand

- fairly tough

- easy to repair or renew

- polyrethane isn't his thing as it is difficult to repair and worse to remove it if doing a refinish

- application

- sand to P240

- clean off with compressed air or vacuum

- wipe with tack rag

- pour it onto surface from jar then wipe on with bounty or similar paper towel

- see details p76 about coverage and wiping off excess

- The custom oil varnish mixture has a number of advantages.

- it is easily wiped on and off with a paper towel.

- it can be wet sanded into the grain to ask as a poor filler.

- the thin coats dry quickly, reducing the opportunity for dust to get trapped in the wet finish.

- this finish is water resistant and tough enough to hold up to everyday use

- it is easy to repair or replace

- it resists yellowing

- it dries hard enough to be rubbed out to a high gloss sheen if desired; if so, see p.75 bottom about filling pores with first coat

- drawbacks

- goes bad in a few weeks

- cloths are very flammable

2024-04-23 It appears Pratt & Lambert no longer makes Varnish

- this 2022 post suggests Arm-R-Seal may not be a great substitute as it adds yellowing.

- Other products to consider might be Odie's Oil, True Oil or Rubio (latter two are available at Klingspor's Woodworking Shop).

- this 2020 post suggests Arm-R-Seal would be a good replacement as it resists yellowing well

- this 2020 post indicates Pratt & Lambert confirmed No 38 is no longer made

- also said that the parent company owns Minwax too

- post #4

- claims 38 was soya oil/alkyd resin formula, and no one else makes one any longer

- try Minwax Fast Dry Oil Varnish

- quite a bit darker than No 38

- linseed oil (drying component) /alkyd varnish formula

- was originally Sherwin Williams Fast Dry Oil Varnish but it was rebranded to Minwax

- I called and it is stocked and a quart is 24.89

- prattandlambert.com says it is now part of Valspar. On Valspar's website, it listed Solon Hardware. I called and they said to call Sherwin Williams

- more info on a fww post

- this post says "Pure Tung oil is superior to Linseed oils. It actually creates a water resistant coating and does not darken over time. It also does not sweat after being warmed up". he recommends realmilpaint.com

Sam Maloof recipe described on thewoodwhisperer

1/3 Boiled Linseed Oil or Tung Oil, 1/3 thinner (mineral spirits, paint thinner, turpentine, naptha), and 1/3 varnish (poly, spar, etc..)

last updated:

Fri 2026-01-09 9:35 AM